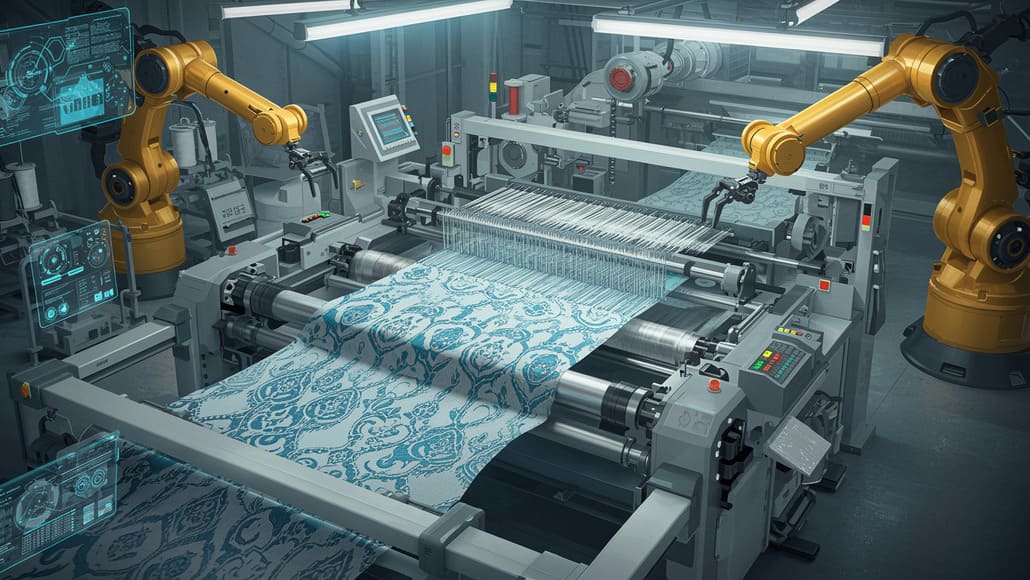

The textile industry, a vital component of the global economy, has been undergoing a significant transformation fueled by advances in technology. Robotics and artificial intelligence (AI) are reshaping the landscape, providing manufacturers with innovative tools to enhance productivity, improve quality, and reduce costs. As businesses consider investing in these automation technologies, it is essential to evaluate the ROI of automation in textiles and understand where these investments are likely to pay off.

Understanding the Need for Automation in Textiles

The textile industry faces numerous challenges, including rising labor costs, increased demand for customization, and the necessity for sustainable practices. Traditional manufacturing methods often struggle to meet these challenges, leading many companies to explore automation solutions. Robotics and AI offer the potential to streamline operations, enhance efficiency, and minimize errors, making them attractive options for manufacturers aiming to maintain competitiveness.

Key Areas Where ROI is Realized

-

Labor Cost Reduction

One of the most immediate benefits of implementing robotic and AI tools in textile manufacturing is the reduction of labor costs. Automation can take over repetitive, labor-intensive tasks, allowing companies to cut down on workforce expenses. For example, robotic sewing machines can work tirelessly without breaks, increasing production rates and reducing the need for manual labor. This shift not only lowers overhead costs but also allows human workers to focus on more complex and value-added tasks.

-

Increased Production Speed and Efficiency

Robotics and AI can significantly enhance production speed and efficiency. Automated systems can operate continuously, often with faster cycle times than human workers. This increase in output can be particularly beneficial in high-demand environments, allowing manufacturers to meet market needs promptly. Additionally, AI algorithms can optimize production schedules, ensuring that resources are used effectively and minimizing downtime.

-

Improved Quality Control

Quality control is critical in the textile industry, where defects can lead to significant losses. AI-powered systems can analyze production data in real-time, detecting anomalies and ensuring that products meet quality standards. By identifying issues early in the production process, manufacturers can reduce waste and avoid costly recalls. The integration of robotics in quality inspection processes can also enhance precision, as machines can detect minute flaws that may be overlooked by the human eye.

-

Enhanced Customization and Flexibility

The demand for customized textile products is on the rise, and automation tools can help manufacturers meet this demand efficiently. AI systems can analyze consumer preferences and trends, enabling companies to quickly adapt their production lines. Robotic systems can also be programmed to handle various styles and designs, allowing for greater flexibility in production without significant setup times. This adaptability can lead to increased customer satisfaction and loyalty, ultimately boosting sales.

-

Sustainability and Waste Reduction

As sustainability becomes increasingly important in the textile industry, automation can play a key role in reducing waste and promoting eco-friendly practices. AI can optimize material usage by analyzing patterns and minimizing excess fabric during cutting processes. Robotics can also facilitate recycling efforts by sorting and processing materials more efficiently than human workers. By investing in automation, companies can not only improve their bottom line but also contribute to a more sustainable future.

Measuring ROI: Key Metrics

To effectively assess the ROI of automation in textiles, companies should establish key performance indicators (KPIs) that align with their business goals. Some essential metrics to consider include:

-

Cost Savings: Calculate the reduction in labor and operational costs resulting from automation.

-

Production Output: Measure increases in production speed and volume attributable to robotic and AI systems.

-

Quality Improvements: Track reductions in defects and returns due to enhanced quality control.

-

Customer Satisfaction: Assess changes in customer feedback and sales volume in response to improved product offerings.

-

Sustainability Goals: Evaluate the impact of automation on waste reduction and resource efficiency.

Challenges and Considerations

While the potential ROI of automation in textiles is promising, businesses must also consider several challenges before making significant investments. Initial capital expenditure for automation technology can be substantial, and companies must ensure they have a clear strategy for implementation.

Moreover, the integration of automation tools can require a shift in workforce dynamics. Employees may need retraining to work alongside robotic systems, and companies must manage the transition carefully to maintain morale and productivity.

Conclusion: The Future of Textile Manufacturing

The ROI of automation in textiles is increasingly becoming a crucial factor for manufacturers seeking competitive advantages. By reducing labor costs, enhancing production efficiency, improving quality, and promoting sustainability, automation investments can lead to significant long-term benefits. However, businesses must approach these investments strategically, measure their impact through relevant KPIs, and address potential challenges to realize the full benefits of automation.

As the textile industry continues to evolve, embracing technology will be essential for companies looking to thrive in an ever-changing market. By leveraging the advantages of robotics and AI, manufacturers can position themselves for success and meet the growing demands of consumers while ensuring a sustainable and efficient production process.