The convergence of technology and textile manufacturing is creating unprecedented opportunities for sustainable innovation in the fashion industry. As tech-enabled textiles emerge as a transformative force, they represent more than just advanced materials—they embody a fundamental shift toward intelligent, environmentally responsible production systems that address the industry’s most pressing sustainability challenges while opening new possibilities for circular economy implementation.

The Evolution of Smart Textile Technology

The landscape of tech-enabled textiles has evolved dramatically from basic functionality to sophisticated systems that integrate sensors, connectivity, and responsive materials into everyday fabrics. These intelligent textiles incorporate electronic components, conductive fibers, and IoT technologies to create garments that can monitor health metrics, regulate temperature, respond to environmental stimuli, and communicate with digital devices seamlessly.

Smart textiles represent a paradigm shift from passive materials to active systems that enhance user experience while addressing sustainability concerns. The University of Southampton and UWE Bristol have demonstrated that wearable electronic textiles can be both sustainable and biodegradable, introducing the concept of Smart, Wearable, and Eco-friendly Electronic Textiles. This approach overcomes traditional challenges where integrating electrical components into conventional textiles complicates recycling due to metals like silver that don’t easily biodegrade.

The healthcare applications of tech-enabled textiles have gained particular momentum, with smart fabrics being developed for continuous vital sign monitoring, rehabilitation support, and medical device integration. These textiles can detect and differentiate multiple stimuli while collecting and storing diverse data signals, creating highly innovative solutions for personalized healthcare applications. The integration of biomonitoring capabilities directly into clothing eliminates the need for separate wearable devices while providing continuous, unobtrusive health data collection.

Temperature regulation represents another significant advancement in smart textile functionality. Phase-change materials embedded within fabric structures can automatically adjust thermal properties based on environmental conditions and body temperature, providing optimal comfort while reducing energy consumption for heating and cooling. This technology has applications ranging from athletic wear to professional uniforms and everyday clothing.

The connectivity features of tech-enabled textiles create new possibilities for data collection and user interaction. Fabrics can now communicate wirelessly with smartphones, fitness tracking applications, and healthcare monitoring systems, creating integrated ecosystems that provide real-time feedback and personalized recommendations for users.

Sustainable Manufacturing Innovations

The development of tech-enabled textiles has catalyzed significant innovations in sustainable manufacturing processes that extend far beyond the incorporation of electronic components. Digital manufacturing techniques are reducing water utilization, material waste, and energy consumption while enabling more precise production control and quality assurance.

Waterless dyeing technologies have emerged as game-changing innovations that eliminate one of the textile industry’s most environmentally damaging processes. Traditional dyeing methods consume vast quantities of water and generate toxic wastewater, but advanced dyeing techniques using supercritical carbon dioxide and other waterless methods can achieve superior color quality while eliminating water pollution entirely.

3D knitting and seamless manufacturing technologies enable zero-waste production by creating finished garments without cutting and sewing operations that typically generate substantial fabric waste. These manufacturing methods can produce complex garment shapes and integrated functionality without traditional assembly processes, reducing material consumption while enabling new design possibilities that incorporate technological features seamlessly.

Bio-based and biodegradable materials are being integrated into tech-enabled textiles to address end-of-life concerns that traditionally made electronic textiles environmentally problematic. Researchers are developing conductive inks and electronic components from organic materials that can decompose safely when garments reach end-of-life, solving the recycling challenges that have limited smart textile adoption.

Digital printing technologies enable on-demand production with minimal setup costs and waste generation. These systems can produce highly detailed and customized designs while incorporating functional elements like conductive pathways and sensor integration areas directly into fabric structures during the printing process.

The integration of artificial intelligence and machine learning into manufacturing processes optimizes production parameters automatically, reducing energy consumption, minimizing material waste, and improving quality consistency. These systems can adjust manufacturing conditions in real-time based on material characteristics, environmental factors, and production requirements.

Circular Economy Integration

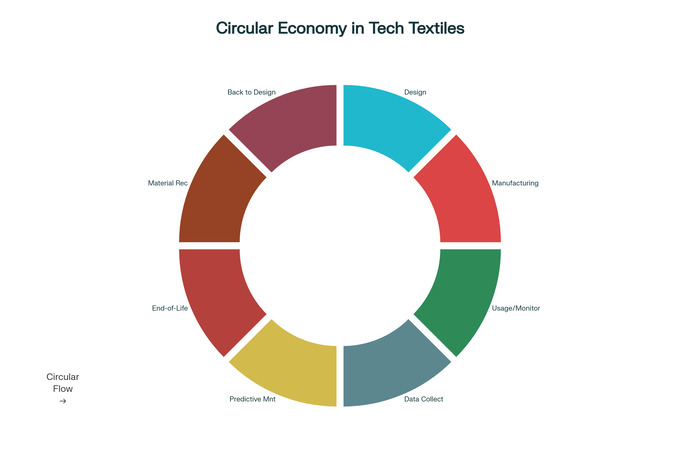

Tech-enabled textiles are uniquely positioned to advance circular economy principles through design features that facilitate reuse, recycling, and resource recovery. The integration of technology into textile products creates opportunities for tracking garment lifecycle data, optimizing usage patterns, and enabling efficient end-of-life processing.

Digital product passports embedded within smart textiles can store comprehensive information about material composition, manufacturing processes, usage history, and recycling instructions. This data enables more effective sorting and processing when garments reach end-of-life while providing transparency throughout the product lifecycle.

Modular design approaches allow technological components to be separated from textile substrates for independent recycling or refurbishment. This design philosophy enables the textile portions to be processed through conventional recycling systems while electronic components can be recovered through specialized e-waste processing facilities.

The monitoring capabilities of smart textiles enable predictive maintenance and usage optimization that extends garment lifespan. By tracking wear patterns, usage frequency, and performance degradation, these systems can provide recommendations for care, repair, and replacement that maximize product utility while minimizing environmental impact.

Blockchain integration creates immutable records of textile lifecycle data that support circular economy initiatives including material provenance tracking, recycling verification, and supply chain transparency. These systems enable verification of sustainability claims while providing data necessary for effective circular economy implementation.

Take-back programs for tech-enabled textiles are being developed to ensure proper processing of smart garments at end-of-life. These programs leverage the connectivity features of smart textiles to notify users when replacement is recommended and facilitate collection and processing through specialized channels.

Environmental Impact and Resource Optimization

The environmental benefits of tech-enabled textiles extend beyond their direct functionality to encompass broader resource optimization throughout their lifecycle. Smart textiles can significantly reduce resource consumption through improved efficiency, extended product lifespan, and optimized usage patterns.

Energy consumption reduction represents a major environmental benefit of tech-enabled textiles. Temperature-regulating fabrics can reduce heating and cooling energy requirements in buildings and vehicles while smart textiles that optimize athletic performance can improve energy efficiency in human activities. The cumulative effect of these efficiency improvements can be substantial at scale.

Water conservation benefits emerge from both manufacturing innovations and product functionality. Waterless production processes eliminate traditional dyeing water consumption while smart textiles that monitor hydration and perspiration can optimize water intake and reduce unnecessary consumption.

Material optimization through smart textiles includes the ability to monitor fabric performance and recommend maintenance or replacement at optimal intervals. This capability prevents premature disposal while ensuring replacement occurs before performance degradation compromises user safety or satisfaction.

The lightweight and multifunctional nature of many tech-enabled textiles reduces material consumption by eliminating the need for separate devices and accessories. A single smart garment can replace multiple traditional products, reducing overall resource consumption and waste generation.

Chemical reduction in textile production has been enabled by advanced manufacturing techniques associated with smart textile development. Digital printing and precision application methods reduce chemical consumption while bio-based materials eliminate toxic substances traditionally used in textile production.

Market Applications and Industry Adoption

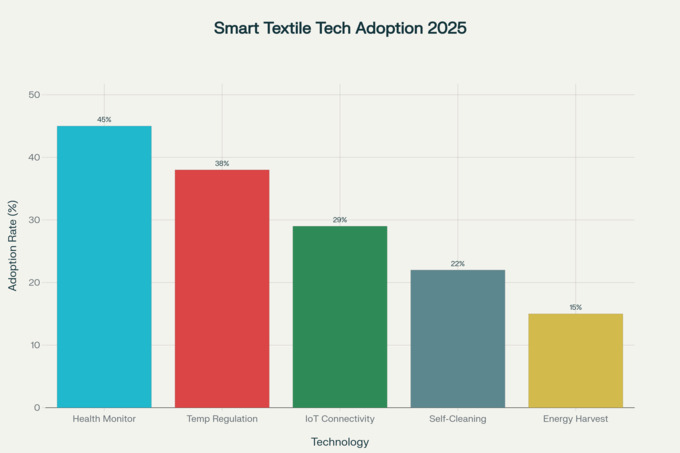

The commercial applications of tech-enabled textiles are expanding rapidly across multiple industry sectors, driven by improved functionality, reduced costs, and increasing consumer acceptance of technology-integrated clothing. Healthcare represents the largest growth opportunity, with smart textiles enabling continuous patient monitoring, remote healthcare delivery, and personalized treatment optimization.

Athletic and performance wear applications leverage the monitoring and environmental response capabilities of smart textiles to optimize athletic performance, prevent injury, and enhance training effectiveness. Major sportswear brands are integrating sensors, temperature regulation, and performance tracking directly into garments to create comprehensive athletic monitoring systems.

Professional and industrial applications include workwear that monitors worker safety, environmental conditions, and productivity metrics. These applications can prevent workplace accidents, optimize work processes, and ensure compliance with safety regulations while providing real-time data for continuous improvement initiatives.

Fashion and lifestyle applications are emerging as technology integration becomes more subtle and aesthetically appealing. Smart textiles can provide functionality like device charging, connectivity, and personalization while maintaining the appearance and feel of traditional high-quality fabrics.

Military and defense applications leverage the durability, monitoring, and communication capabilities of smart textiles for personnel protection, situational awareness, and mission optimization. These applications often drive technological advancement that subsequently benefits civilian applications.

The integration of smart textiles into automotive, aerospace, and architectural applications creates new markets that extend beyond traditional clothing and textile applications. These technical textiles can provide structural monitoring, environmental control, and user interface capabilities in complex systems.

Manufacturing Scalability and Cost Considerations

The transition from laboratory prototypes to commercial-scale production represents a critical challenge for tech-enabled textiles sustainable solutions. Manufacturing scalability requires addressing technical complexity, cost optimization, and quality control while maintaining the environmental benefits that justify smart textile development.

Production volume economics currently favor traditional textiles due to established manufacturing infrastructure and economies of scale. However, the value proposition of tech-enabled textiles can justify higher per-unit costs when functionality benefits are considered. As production volumes increase and manufacturing processes mature, cost parity with traditional textiles becomes achievable.

Supply chain integration challenges include coordinating textile manufacturing with electronics production, ensuring component compatibility, and managing quality control across diverse manufacturing processes. Successful smart textile production requires closer collaboration between traditionally separate industries.

Quality assurance systems must address both textile performance characteristics and electronic functionality while ensuring long-term reliability under real-world usage conditions. This requires development of new testing methods and standards that encompass the unique requirements of tech-enabled textiles.

Standardization efforts are essential for enabling broader adoption of tech-enabled textiles sustainable solutions. Industry organizations are developing standards for connectivity protocols, safety requirements, and performance specifications that will facilitate interoperability and consumer confidence.

Investment in manufacturing infrastructure specifically designed for tech-enabled textiles is increasing as major textile companies recognize the strategic importance of smart textile capabilities. This investment is reducing production costs while improving quality and enabling larger-scale production.

Future Innovation Trajectories

The future development of tech-enabled textiles sustainable solutions will be shaped by advances in materials science, electronics miniaturization, and sustainable manufacturing processes. Emerging technologies promise to address current limitations while opening entirely new application possibilities.

Nanotechnology integration will enable more sophisticated functionality at reduced scale and cost while potentially improving biodegradability and environmental compatibility. Nanofibers and nanocomposites can provide enhanced performance characteristics while reducing material consumption.

Energy harvesting capabilities integrated directly into textiles could enable self-powered smart garments that eliminate battery requirements while providing continuous operation. Photovoltaic fibers, piezoelectric materials, and thermoelectric generators can convert ambient energy into electrical power for textile-integrated electronics.

Artificial intelligence integration at the textile level could enable garments that learn user preferences, adapt functionality automatically, and provide predictive recommendations for health, performance, and maintenance. These capabilities would represent a significant advancement beyond current sensor-based systems.

Biotechnology applications may enable the development of living textiles that can repair themselves, adapt to environmental conditions, and provide biological functionality like air purification or antimicrobial protection. These bio-integrated systems could revolutionize textile functionality while supporting circular economy principles.

The convergence of tech-enabled textiles with other emerging technologies including augmented reality, 5G connectivity, and edge computing will create new possibilities for textile-based interfaces and experiences that extend far beyond current smart textile capabilities.

Industry Transformation and Strategic Implications

The advancement of tech-enabled textiles sustainable solutions is catalyzing broader transformation throughout the textile and fashion industries. Traditional business models, supply chain structures, and competitive dynamics are evolving in response to technological capabilities and sustainability requirements.

Vertical integration strategies are becoming more attractive as companies seek to control the complex interactions between textile manufacturing and technology integration. This trend may favor larger companies that can invest in comprehensive capabilities while creating opportunities for specialized suppliers that can serve multiple brands.

Partnership models between textile companies and technology firms are becoming essential for accessing the diverse expertise required for smart textile development. These collaborations are creating new industry ecosystems that combine traditional textile knowledge with cutting-edge technology capabilities.

The intellectual property landscape for tech-enabled textiles is becoming increasingly complex as innovations span multiple technology domains. Companies must develop sophisticated IP strategies that protect innovations while enabling collaboration with partners across different industries.

Consumer education and market development represent significant challenges and opportunities as smart textiles transition from niche applications to mainstream adoption. Success requires demonstrating clear value propositions while addressing consumer concerns about privacy, durability, and environmental impact.

The evolution toward tech-enabled textiles sustainable solutions represents a fundamental transformation that extends far beyond product innovation to encompass manufacturing processes, business models, and industry structure. As these technologies mature and achieve commercial scale, they promise to deliver substantial environmental benefits while creating new possibilities for functionality and user experience that could redefine the role of textiles in daily life.