Key Takeaways

- Zero-waste design requires creative problem-solving and constraint-driven innovation generating distinctive aesthetic characteristics

- Modular pattern systems enable multiple garment configurations from single fabric pieces, extending functionality and consumer value

- Digital design tools enable sophisticated pattern optimization identifying optimal arrangements maximizing material utilization

- Zero-waste construction creates inherent limitation and uniqueness differentiating pieces from industrially manufactured alternatives

- The technical challenges of zero-waste design have stimulated innovations in seaming techniques, construction methodologies, and aesthetic approaches

- Scaling zero-waste production requires manufacturing infrastructure and designer expertise currently concentrated in premium markets but increasingly accessible

Understanding the Waste Crisis and Design Solution

The global fashion industry generates approximately 92 million tons of textile waste annually, with manufacturing waste representing substantial portion. Traditional pattern cutting methodologies produce waste as inevitable byproduct—patterns laid out on fabric inevitably generate offcuts and scraps. The industry has historically treated this waste as unavoidable cost of production. Zero-waste design challenges this assumption fundamentally, asserting that thoughtful pattern design can achieve 100% fabric utilization through innovation rather than accepting waste as inevitable.

Zero-waste design emerged from recognition that constraint-driven problem-solving frequently generates innovation superior to unrestricted conventional approaches. By requiring designers to utilize every fabric fragment, zero-waste methodology eliminates waste while forcing creative solutions generating distinctive, innovative products. Rather than representing compromise constraining design possibility, zero-waste requirements catalyze innovation creating aesthetic and functional characteristics impossible within conventional design frameworks.

The environmental imperative underlying zero-waste design represents compelling fashion industry response to sustainability crisis. Reducing manufacturing waste directly decreases resource extraction requirements, chemical processing needs, and landfill burden. Zero-waste design addresses environmental concerns without requiring consumer sacrifice—pieces designed through zero-waste methodologies function normally while eliminating manufacturing waste completely.

The Design Methodology of Zero-Waste Pattern Making

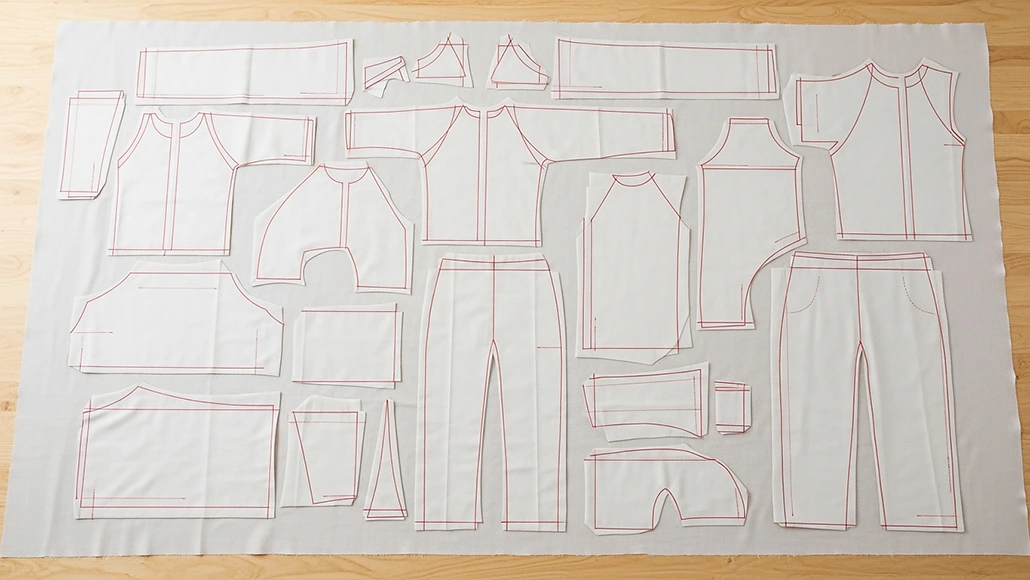

Zero-waste pattern making requires entirely distinct design approach compared to conventional garment construction. Traditional methodology conceives individual garment components sequentially, arranging patterns on fabric to achieve acceptable material usage. Zero-waste methodology approaches design holistically, conceptualizing complete garment as integrated system where all pattern pieces interlock eliminating negative space and waste.

The technical challenges of zero-waste design prove surprisingly productive creatively. Designers cannot simply modify garment dimensions to reduce waste—pieces must maintain functional integrity and aesthetic integrity despite utilization constraints. These requirements force consideration of garment construction from fundamental principles,frequently generating innovative approaches impossible within conventional design frameworks. The constraint becomes creative catalyst rather than limiting burden.

Digital design tools have transformed zero-waste pattern development from largely artisanal practice to increasingly systematic methodology. Sophisticated software enables designers to visualize complete patterns, simulate material behavior, and optimize arrangements rapidly. Machine learning algorithms assist in identifying optimal pattern layouts, dramatically improving designer efficiency while expanding creative possibility. These technological tools have made zero-waste design increasingly accessible beyond elite luxury designer segments.

Modular Design and Multi-Use Garment Systems

Modular zero-waste design enables creation of garments with multiple configuration possibilities, extending functionality and consumer value. Pattern pieces designed for primary garment purpose can be reconfigured into alternative styles through different assembly methodologies. Garment components might function as interchangeable pieces, enabling consumers to customize appearance or adapt function addressing evolving needs.

The modularity inherent in zero-waste design aligns perfectly with circular fashion trends emphasizing extended product lifecycles. Modular pieces can be reconfigured as aesthetics evolve or wearer preferences change. Components can be replaced independently without discarding entire garment. This design philosophy directly supports sustainability objectives through extended product utility and reduced consumption.

Consumers increasingly appreciate modular design enabling personalization and flexibility. Rather than acquiring numerous garments addressing different occasions, modular systems enable fewer pieces delivering greater functional variety. This efficiency aligns with contemporary consumer preference for quality, versatility, and intentional curation rather than rapid consumption and constant novelty.

Aesthetic Innovation Through Design Constraint

Zero-waste design constraints frequently generate distinctive aesthetic characteristics impossible to achieve through conventional approaches. Visible seaming patterns reflecting optimal material utilization become design features rather than functional necessities. Unconventional silhouettes resulting from geometric puzzle-solving create unique visual signatures. The garment structure itself communicates thoughtful design and intentional creativity.

This aesthetic authenticity represents significant brand differentiation opportunity. Contemporary consumers increasingly appreciate design honesty—visible construction reflecting actual design methodology rather than disguised functionality. Zero-waste garments communicate design innovation and environmental commitment through physical appearance, creating brand storytelling opportunity beyond conventional marketing approaches.

The distinctive characteristics emerging from zero-waste design methodology appeal particularly to consumers valuing individuality and meaningful production narratives. Garments evidencing thoughtful design and environmental consideration resonate with conscious consumers willing to invest in pieces reflecting shared values.

Scaling Zero-Waste Production

The primary challenge in zero-waste design scaling involves manufacturing infrastructure requirements. Zero-waste patterns frequently require sophisticated cutting and construction techniques demanding specialized training and equipment. Production speeds differ substantially from conventional manufacturing optimized for rapid volume production. These constraints have historically limited zero-waste production to premium markets where elevated prices justify specialized production approaches.

Contemporary technological advancement is enabling zero-waste methodology scaling. Advanced cutting machinery can precisely execute complex zero-waste patterns. Computer-aided design systems enable rapid pattern development and optimization. Improved training and information dissemination support skill development across production facilities. These advances progressively make zero-waste approaches economically viable across wider price segments.

Fashion brand investment in zero-waste production capacity demonstrates commitment to scaling sustainable methodologies. Brands establishing dedicated zero-waste production lines position themselves advantageously within trend toward environmental responsibility. As manufacturing scales and techniques refine, zero-waste production costs continue declining, potentially transitioning from premium positioning to mainstream competitive feature.

Design Innovation and Technical Advancement

Zero-waste design has catalyzed remarkable innovation in construction techniques and material utilization. Designers have developed novel seaming methodologies enabling fabric fragments to be integrated seamlessly. Innovative approaches to garment assembly create visual appeal from structural necessity. These technical developments represent genuine advancement in design and manufacturing capability, expanding creative possibility for all practitioners.

The circulation of zero-waste design knowledge through educational initiatives, industry publications, and designer collaborations has democratized these advanced techniques. Emerging designers increasingly learn zero-waste methodology alongside conventional approaches, preparing next generation of designers to compete in increasingly sustainability-conscious market.

The symbiotic relationship between constraint and innovation becomes evident in zero-waste design development—the requirement to eliminate waste drives innovations benefiting all garment production, not merely zero-waste specialists. Improved pattern optimization, innovative construction techniques, and enhanced design efficiency generate advantages extending throughout fashion industry.

Consumer Value and Sustainability Communication

Zero-waste garments communicate compelling sustainability narratives enabling brands to achieve premium positioning while delivering genuine environmental benefit. Consumers understand that zero-waste production eliminates specific waste sources—they appreciate design decisions prioritizing environmental responsibility without compromise to quality or function. This transparency builds consumer trust and loyalty.

The premium pricing zero-waste pieces command reflects both specialized production requirements and consumer valuation of environmental benefits. Consumers increasingly demonstrate willingness to invest substantially in products delivering measurable sustainability advantage. Zero-waste design provides quantifiable environmental benefit—complete waste elimination from manufacturing process—enabling credible sustainability positioning.

The market success of zero-waste garments demonstrates that sustainability and premium positioning reinforce rather than contradict one another. Consumers investing in zero-waste pieces view purchases as supporting brand environmental leadership while acquiring distinctive products reflecting personal values.

The Future of Zero-Waste Design

The trajectory of zero-waste design suggests continued expansion from specialty positioning toward mainstream adoption. As manufacturing technology improves and techniques proliferate, zero-waste production costs will continue declining. Regulatory pressure regarding textile waste may accelerate industry adoption, making zero-waste approaches increasingly necessary rather than voluntary. The coming decade may witness zero-waste design transitioning from niche innovation to industry standard expectation.

The ultimate realization of zero-waste fashion would involve elimination of manufacturing waste throughout apparel industry. Rather than representing niche practice, zero-waste methodology would become standard approach integrated throughout design education and manufacturing processes. This transformation would represent remarkable evolution from current state where substantial manufacturing waste remains largely accepted as inevitable industry byproduct. The fashion industry’s future sustainability depends substantially on whether zero-waste methodology successfully scales from experimental practice to universal implementation.