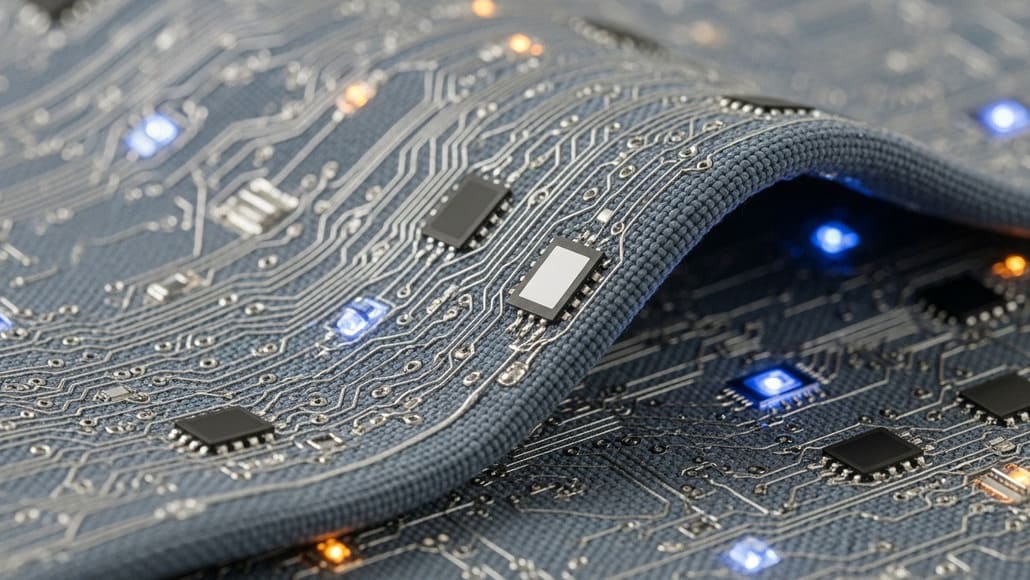

The Global Electronics Association, based in Bannockburn, Illinois, has officially introduced IPC-8911, the first-ever global standard for classifying, designating, and qualifying conductive yarns used in electronic textiles (e-textiles). This groundbreaking initiative aims to tackle ongoing challenges in supply chain communication, material selection, and product testing within the expanding e-textiles market.

By maintaining the IPC brand for industry standards and certification programs, the Global Electronics Association underscores the critical need for dependable and consistent products in the industry. Developed by the IPC Conductive Yarns for E-Textiles Test Methods Task Group, the IPC-8911 standard outlines essential yarn categories, presents a standardized designation system, and specifies qualification and conformance requirements tailored for conductive yarns.

Supported by eight new testing methods, IPC-8911 will evaluate important performance metrics such as conductivity, mechanical durability, and resilience to environmental and chemical factors. These comprehensive assessments will ensure manufacturers can effectively gauge their materials’ performance.

The task group included leading experts from both the textile and electronics sectors, with Joe Geiger from Bally Ribbon Mills and Sahar Rostami from Meta taking prominent roles. Geiger remarked, “This standard provides manufacturers with the tools they need to accurately specify their yarn requirements while helping suppliers understand the electrical specifications their products must fulfill. It clarifies the entire process, acting as a comprehensive guide for building robust e-textile systems.”

Rostami emphasized, “IPC-8911 eliminates ambiguity, offering developers, researchers, and engineers a common framework that accelerates research and development by reducing the redundancy in selecting and testing conductive yarns.”

By clearly defining the performance attributes and communication protocols for conductive yarns, the IPC-8911 standard supports rapid product development, more reliable sourcing, and improved overall reliability for a variety of e-textile applications, ranging from consumer products to medical devices and aerospace technologies.

Moreover, this new standard reinforces the position of conductive yarns as vital components in the electronic landscape, fostering enhanced collaboration between yarn suppliers, product developers, and brands.