Researchers at the US National Institute of Standards and Technology (NIST) have unveiled a groundbreaking database designed to streamline the recycling of textile fibres. This innovative resource, called the Near-Infrared Spectra of Origin-defined and Real-world Textiles (NIR-SORT), serves as a comprehensive collection of molecular “fingerprints” for various fabric types, enabling quicker and more efficient sorting processes at recycling facilities.

The NIR-SORT database includes data from 64 different fabric types, ranging from pure fibres like cotton and polyester to blends such as spandex mixtures. It also incorporates real-world textiles sourced from thrift stores, ensuring practical applicability in diverse scenarios.

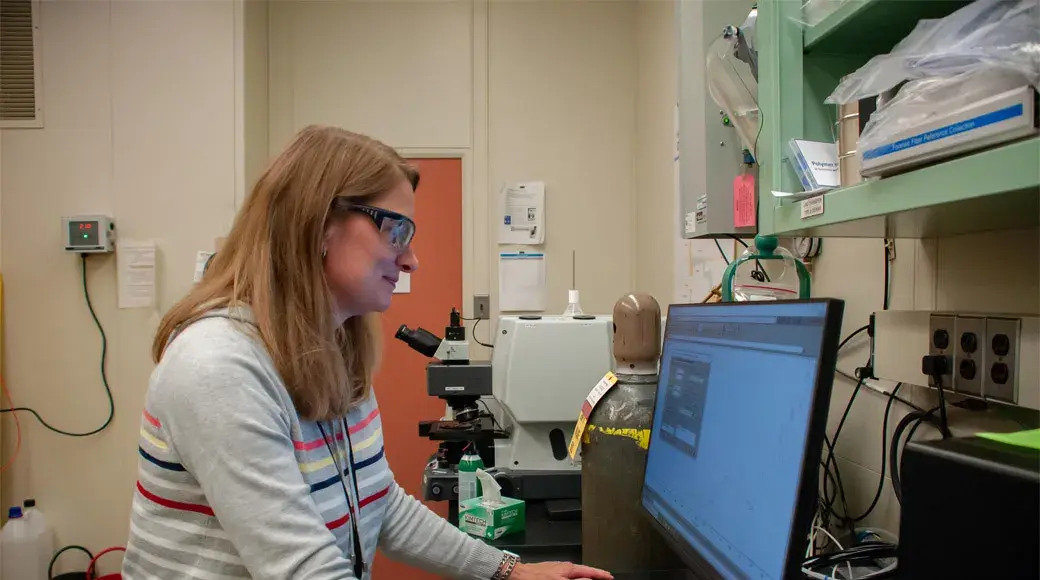

Manufacturers of near-infrared (NIR) scanning systems can use the database to train and refine their sorting algorithms, enhancing the accuracy and effectiveness of their machines. “This reference data will help improve sorting algorithms and unlock the potential for high-throughput sorting, which requires less manual labour,” explained Amanda Forster, a materials research engineer at NIST. She added that this advancement could lower costs and boost efficiency, making textile recycling a more economically feasible option.

To create the database, researchers employed near-infrared spectroscopy, a powerful lab technique that analyzes how light interacts with materials. By measuring how light scatters off or passes through a fabric sample, the method generates a unique “fingerprint” that identifies the type of fibres present. This high-quality reference data is essential for improving sorting technologies, particularly as manufacturers increasingly rely on machine learning and AI to optimize their systems.

The NIST database, freely accessible through its public data repository, is expected to be a valuable tool for recycling equipment manufacturers. By providing precise spectral data, it aims to reduce errors in fabric identification and increase the percentage of textiles that can be successfully recycled.

With NIST’s expertise as the nation’s premier measurement institute, the database ensures a level of accuracy that could revolutionize the textile recycling industry, promoting sustainability and reducing the burden on landfills.