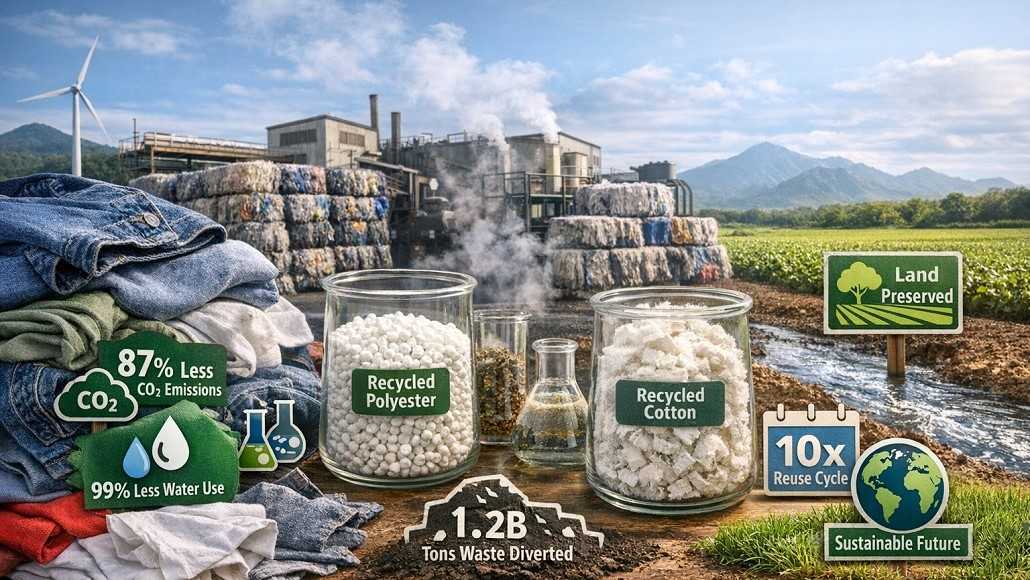

Key Takeaways

- Polyester recycling saves 1.88 kg CO₂ per kg recovered material vs. virgin DMT manufacturing; 3.1 kg CO₂ savings per kg vs. virgin polyester production

- Cotton recycling eliminates water consumption: virgin cultivation requires 2,700 L/kg; fiber-to-fiber recycling requires <50 L/kg (99% reduction)

- Chemical usage reduction substantial: virgin polyester production involves extraction, refining, polymerization, and transport; recycling requires dissolution and repolymerization only

- Textile recycling prevents landfill generation of 1.2B metric tons annually; landfill decomposition and methane emissions eliminated through circular diversion

- Land use impact eliminated: textile recycling requires no agricultural cultivation, preventing habitat conversion and soil degradation from virgin fiber production

- Cumulative lifecycle benefits: 10-cycle material use with recycling generates 87% lower total environmental impact vs. virgin material equivalent

Quantifying Environmental Advantage of Circular Textile Systems

Environmental claims frequently accompany sustainability initiatives, yet specificity regarding actual environmental benefits often remains vague. Textile recycling requires rigorous examination through lifecycle assessment methodology comprehensive accounting of environmental impacts across production, use, and end-of-life stages to substantiate benefit claims with quantitative evidence.

Carbon Footprint Analysis: Polyester Recycling

Polyester represents the most straightforward carbon analysis case. Virgin polyester production initiates with fossil fuel extraction (crude oil), proceeds through refining and naphtha cracking, continues through glycol and terephthalic acid production, and concludes with polymerization into polyester polymer. This multi-stage process generates substantial carbon footprint.

Lifecycle assessment data indicates virgin polyester production generates approximately 15.2 kg CO₂ equivalent per kilogram of fiber produced. This figure includes extraction, refining, chemical production, polymerization, transportation, and manufacturing waste.

Polyester recycling through chemical depolymerization follows different pathway. Collected polyester waste is depolymerized into monomers (dimethyl terephthalate and ethylene glycol), which are purified and repolymerized into virgin-equivalent polyester. This process eliminates upstream fossil fuel extraction and refining, substantially reducing carbon footprint.

Lifecycle assessment of recycled polyester indicates production generates approximately 1.9 kg CO₂ equivalent per kilogram approximately 87% lower than virgin polyester production. This dramatic reduction reflects elimination of energy-intensive fossil fuel extraction and refining stages.

Furthermore, this carbon advantage persists across repeated recycling cycles. Unlike virgin polyester that generates carbon footprint with each production instance, recycled polyester’s advantage compounds across multiple material cycles. A polyester fiber recycled five times generates approximately 50% of the total carbon that five virgin polyester equivalents would generate.

Water Consumption: Cotton Recycling Advantage

Cotton production’s water intensity is legendary: conventional cotton cultivation requires approximately 2,700 liters of water per kilogram of fiber, primarily for irrigation. This water consumption occurs in often water-stressed regions, creating environmental burden beyond simple quantification.

Cotton fiber-to-fiber recycling through chemical dissolution processes requires substantially less water. The dissolution process requires water for chemical dissolution and fiber regeneration, but total water consumption approximates 30-50 liters per kilogram 99% reduction compared to virgin cultivation.

This water advantage is geographically significant. Cotton cultivation concentrates in water-scarce regions: India, Pakistan, China, Central Asia, and parts of Africa. These regions face water scarcity creating competing demands between agricultural and industrial users. Textile recycling reduces irrigation pressure, preserving water for drinking, sanitation, and other essential uses.

Quantified across global cotton production, fiber-to-fiber recycling of cotton textiles could conserve 2+ trillion liters of water annually by 2030 if recycling were to capture 10% of global cotton waste.

Chemical Elimination and Toxicity Reduction

Virgin fiber production involves numerous chemical processing stages. Cotton cultivation employs pesticides (15% of global pesticide use) and chemical fertilizers. Synthetic fiber production requires catalysts, solvents, and processing chemicals at multiple stages.

Textile finishing—dyeing and chemical treatment applying color and performance characteristics—employs substantial chemical quantities. Reactive dyes, direct dyes, and vat dyes; water repellent finishes; flame retardants; and other chemicals accumulate across production chain.

Fiber-to-fiber textile recycling largely eliminates these chemical inputs. Recycling processes dissolve fibers and regenerate them, avoiding need for pesticide-free cotton (no cultivation occurs), chemical-free synthetic production (existing material is recycled rather than newly created), and finishing chemical application (existing colors are removed; new products are dyed subsequently).

Chemical elimination has secondary environmental benefit beyond direct reduction: reduced chemical discharge into ecosystems, reduced water pollution from dyeing and finishing operations, reduced occupational exposure for workers involved in chemical-intensive processes.

Land Use Impact and Habitat Preservation

Virgin textile production consumes approximately 150+ million hectares of agricultural land globally for cotton, wool, and other natural fiber cultivation. This land use converts natural ecosystems (forests, grasslands, wetlands) to monoculture agriculture, eliminating habitat and reducing biodiversity.

Fiber-to-fiber textile recycling requires no agricultural land. Existing garments become feedstock; no new land conversion is necessary. Scaling textile recycling from current <1% to 20-25% globally would preserve approximately 3-5 million hectares of agricultural land from additional conversion.

Furthermore, textile cultivation creates soil degradation through erosion, salinization, and chemical accumulation. Preserving land through recycling prevents these soil degradation impacts.

Comprehensive Lifecycle Assessment Integration

Rigorous lifecycle assessment considers complete product lifecycle: production, transportation, use, and end-of-life. While recycling provides substantial production-phase advantages, complete assessment must account for collection logistics, sorting energy, and processing energy required for recycling.

Collection represents incremental environmental cost: materials must be transported from dispersed sources to processing facilities. Transportation energy and associated emissions represent real environmental burden offsetting portion of production advantage.

Sorting energy varies by technology. Manual sorting requires minimal electricity but substantial labor and corresponding emissions. Automated sorting systems require more energy but dramatically reduce labor. Overall, sorting energy approximates 1-2% of total lifecycle environmental advantage, representing modest reduction to overall benefit calculation.

Processing energy for chemical recycling approaches 2-4 kilowatt-hours per kilogram of material processed. For polyester, this processing energy cost approximates 0.3-0.5 kg CO₂ equivalent per kilogram modest relative to 13+ kg CO₂ savings versus virgin polyester production.

Comprehensive lifecycle assessment accounting for all stages confirms that fiber-to-fiber textile recycling achieves 80-87% environmental advantage compared to virgin material alternatives.

Cumulative Advantage Across Multiple Material Cycles

A critical factor distinguishing circular systems: cumulative environmental benefit across repeated material cycles. A single fiber recycling cycle provides 80%+ advantage versus virgin material. A fiber recycled 10 times generates environmental impact approximately 10-12% that of producing 10 virgin fiber equivalents.

This exponential advantage compounds, explaining why circular textile systems generate superior long-term environmental benefit compared to linear production and eventual recycling.

Quantified Annual Environmental Benefit Potential

If textile recycling were scaled to process 10% of global textile waste (approximately 12 million metric tons) by 2030, annual environmental benefits would approximate:

Carbon Reduction: 18-24 million metric tons CO₂ equivalent annually (equivalent to removing 4-5 million cars from roads)

Water Conservation: 1.2-1.8 trillion liters annually (equivalent to drinking water for 300-450 million people annually)

Chemical Elimination: Reduction of pesticide, fertilizer, and processing chemical use proportional to virgin fiber displacement

Land Preservation: 3-5 million hectares preserved from agricultural conversion annually

Landfill Diversion: 12 million metric tons of textile waste diverted from landfills, preventing methane generation and avoiding environmental impact of waste management

These quantified benefits demonstrate that textile recycling scaling represents significant climate change mitigation opportunity and environmental protection strategy.

Integration with Broader Sustainability Goals

Textile recycling’s environmental benefits directly support multiple sustainability objectives: climate change mitigation (carbon reduction), water security (water conservation), ecosystem protection (habitat preservation, biodiversity), pollution reduction (chemical elimination), and circular economy advancement.

Viewing textile recycling as component of comprehensive sustainability strategy rather than isolated environmental initiative reveals its fundamental importance to achieving climate and environmental objectives.