The Silent Revolution in Intimate Apparel Comfort

The intimate apparel industry stands at the threshold of a transformative era, one where the fundamental expectations of comfort have been fundamentally redefined through advanced textile engineering. Today’s consumers no longer view undergarments as mere functional basics; instead, they demand garments that conform seamlessly to their bodies while offering performance characteristics once reserved for athletic wear. This paradigm shift has catalyzed an unprecedented wave of innovation in stretch fabric technology, with manufacturers investing heavily in stretch innovation intimate apparel comfort solutions that blur the line between everyday comfort and specialized performance wear.

The evolution of stretch fabrics has always been intrinsically linked to human comfort, yet the sophistication of modern elastomeric engineering has elevated this relationship to entirely new dimensions. Modern intimate apparel now incorporates sophisticated yarn engineering, multidirectional elasticity systems, and adaptive fit technologies that work harmoniously to deliver what industry professionals call “second-skin comfort”—a sensation that garments feel like natural extensions of the body rather than external constraints. This comprehensive exploration examines how stretch innovation is revolutionizing intimate apparel through engineered elastomers, cutting-edge fiber science, and design methodologies rooted in biomechanical understanding.

The Engineering Behind Stretch Innovation

Understanding Elastomeric Fiber Architecture

The foundation of modern stretch innovation rests upon sophisticated elastomeric fiber systems that have evolved considerably from their predecessors. Traditional spandex, also known as elastane, represented a breakthrough when first introduced to intimate apparel markets, yet contemporary alternatives are expanding the possibilities of what comfortable, high-performing intimate wear can achieve. Spandex’s fundamental characteristic—its ability to stretch to 200 percent of its original length and snap back instantaneously—remains unmatched in commercial applications, though its petroleum-based origins and recycling challenges have motivated alternative development.

The yarn engineering process that creates these elastic fibers involves an intricate interplay of polymer chemistry and mechanical processing. Elastomeric polymers are spun through specialized mechanical systems that orient molecular chains in specific configurations, establishing both the permanent shape and the capacity for reversible deformation. Within core-spun yarn structures commonly used in intimate apparel, elastic fibers are wrapped concentrically by conventional fibers such as cotton or polyester. This architectural arrangement means that during garment wear, the elastomeric core handles the primary stretch and recovery functions while the outer wrapping fibers contribute breathability, softness, and dimensional stability.

Heat setting represents a critical stage in yarn engineering that stabilizes elastic properties. When cotton-spandex blends undergo carefully controlled thermal treatment, the molecular structure reorganizes, and the elastic forces condense to predetermined levels. This controlled compression of elastic forces ensures that intimate apparel maintains its shape-retention properties across countless wear and wash cycles—a characteristic that distinguishes premium comfort wear from disposable alternatives.

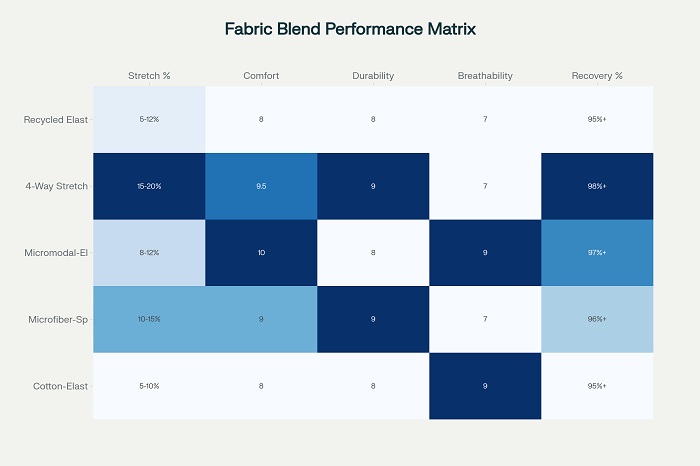

This comparative analysis reveals that micromodal-elastane blends deliver superior comfort ratings while four-way stretch constructions provide maximum directional elasticity and recovery capabilities, establishing the performance benchmarks that define contemporary premium intimate apparel.

Multidirectional Elasticity: Beyond Two-Dimensional Stretch

The most significant advancement in recent stretch fabric innovation involves the development of true multidirectional elasticity systems. Traditional intimate apparel relied on two-directional stretch, where fabrics accommodated movement primarily along the warp and weft directions. Modern four-way stretch technology, however, enables fabric to expand uniformly in all directions simultaneously—vertically, horizontally, and diagonally—creating what textile engineers refer to as omnidirectional flexibility.

This achievement stems from specialized circular knit construction techniques and the strategic distribution of elastomeric fibers throughout the fabric’s three-dimensional matrix. Unlike conventional weaving or single-direction knitting, four-way stretch construction integrates elastic components across both the warp and weft systems, with precise gauge and tension controls determining ultimate stretch potential. The result is a fabric architecture where elastic recovery operates across multiple planes, accommodating the complex, multidirectional movements that characterize authentic human motion.

The technical advantage extends beyond simple comfort perception. Research demonstrates that four-way stretch fabrics reduce seam stress by approximately forty percent compared to traditional two-way alternatives, effectively extending garment lifespan and reducing fabric failure points. More importantly, this multidirectional elasticity eliminates the bunching and bagging phenomena common in conventional elastic systems, maintaining a smooth, contoured silhouette regardless of wearer movement intensity.

Engineered Fibers: The Next Generation of Spandex Alternatives

Sustainable Elastomers Reshaping the Industry

The textile industry’s accelerating shift toward sustainability has prompted development of innovative elastomeric alternatives that maintain performance parity with conventional spandex while reducing environmental impact. YULASTIC, a natural rubber-based fiber derived from Hevea brasiliensis trees, represents one breakthrough approach to sustainable stretch innovation. Unlike petroleum-derived elastane, YULASTIC offers full renewability and actually outperforms synthetic alternatives in elastic recovery metrics, demonstrating that ecological responsibility and technical excellence are not inherently contradictory objectives.

NEOLAST, developed collaboratively by major athletic brands and advanced materials manufacturers, exemplifies another pathway forward. This recyclable elastoester polymer utilizes solvent-free melt-extrusion processes, fundamentally reducing chemical complexity while improving environmental compatibility. Both alternatives represent what industry analysts term “performance-driven sustainability”—innovations where ecological benefits emerge directly from enhanced technical capabilities rather than representing performance compromises.

The adoption trajectory of these alternatives within intimate apparel specifically reveals consumer receptiveness to innovative elastomeric systems. Market research indicates that consumers actively seek sustainable intimate wear options, with purchasing preferences demonstrating willingness to prioritize ecological factors alongside conventional comfort metrics. This market response validates continued investment in elastomer innovation, particularly within categories where intimate contact with skin demands both exceptional performance and material safety.

Yarn Engineering and Elastic Recovery Science

The sophisticated science underpinning elastic recovery involves understanding polymer molecular dynamics at scales invisible to conventional observation. When elastomeric polymers experience deformation, their molecular chains uncoil and align directionally. Superior elastic recovery occurs when these same chains rapidly reorient to their original crystalline configurations upon stress removal. This molecular-level recovery capability distinguishes premium stretch fabrics from inferior alternatives that exhibit permanent deformation or reduced elasticity after repeated stretching cycles.

Modern yarn engineers manipulate several parameters to optimize elastic recovery characteristics. Denier specifications—the weight of yarn expressed in standardized units—directly influence stretch behavior and recovery speed. Lower denier elastomeric filaments demonstrate faster recovery kinetics but potentially reduced strength, while higher denier systems sacrifice some recovery velocity to enhance overall durability. The selection of optimal denier ranges for specific intimate apparel applications requires deep understanding of both garment construction requirements and intended wearer movement patterns.

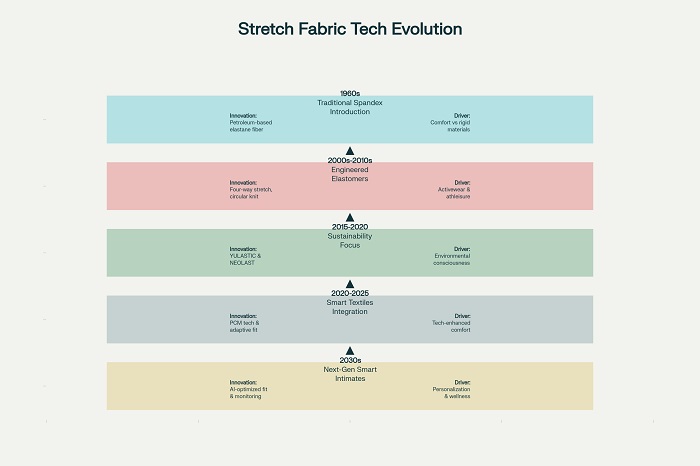

This evolutionary progression illustrates how stretch fabric technology has accelerated from single-innovation petroleum-based systems toward multi-dimensional, sustainable, and responsive material architectures, fundamentally expanding intimate apparel performance capabilities across each successive decade.

Body Mapping and Adaptive Fit Technology

Biomechanical Design Principles in Intimate Apparel

The concept of body mapping in intimate apparel represents a fundamental departure from conventional pattern construction, where identical fabric specifications are applied uniformly across entire garments. Body mapping technology instead approaches fabric construction as a localized optimization challenge, engineering specific zones within single garments to deliver precisely calibrated performance characteristics aligned with anatomical and biomechanical realities.

This zone-specific approach recognizes that different body areas experience distinctly different mechanical demands during routine wear and movement. Areas prone to perspiration accumulation require enhanced moisture-wicking capacity, while regions subject to repetitive stress need superior elastic recovery characteristics. The lower back, underarm regions, and behind-knee zones each present unique thermal and kinetic requirements that uniform fabric construction cannot adequately address.

Seamless construction techniques enable true body mapping implementation without compromising fabric integrity. Modern circular knitting machines can vary thickness, ventilation density, and elastomeric content within single continuous knit operations, eliminating the necessity for pattern pieces to be sewn together. This technological capability delivers multiple advantages: reduced seam-related irritation, improved fit precision, enhanced fabric utilization efficiency, and superior garment durability by eliminating stress concentration points where stitching traditionally occurs.

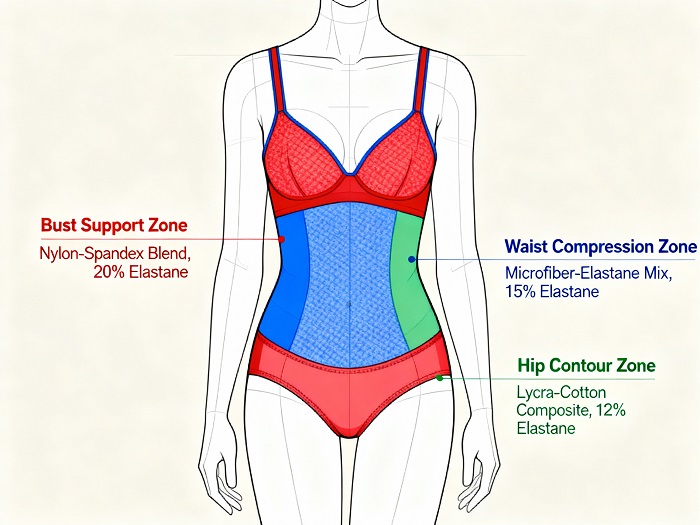

The visualization demonstrates how body mapping technology translates design concepts into specific garment zones, each engineered with distinct fabric specifications, elastane percentages, and specialized material properties optimized for localized biomechanical demands.

Targeted Stretch Zones and Comfort Integration

Contemporary intimate apparel manufacturers implement body mapping through strategic elastomeric fiber concentration in specified zones. Areas anticipating minimal movement receive lower elastane percentages (typically 5-8 percent), conserving fiber expense while maintaining adequate stretch. Regions subject to substantial extension forces incorporate elevated elastane content (12-18 percent), ensuring robust elastic recovery without excessive compression sensation.

The integration of specialized materials within body-mapped garments extends beyond simple elastane concentration variations. Advanced intimate wear increasingly incorporates phase change materials (PCMs) in thermal regulation zones, micromodal or modal fibers in moisture-sensitive areas, and even antimicrobial fiber technologies in hygiene-critical regions. These localized material variations create what designers term “engineered comfort profiles”—garments calibrated to support human physiology rather than imposing external constraints upon it.

Market Demand and Consumer Preferences

The Comfort-Performance Paradigm Shift

Contemporary intimate apparel consumers have fundamentally reframed their purchasing criteria around comfort as the paramount consideration. Market research demonstrates that over seventy-one percent of female shoppers now prioritize comfort as the decisive factor when selecting bras and undergarments, representing a substantial increase from previous decades when aesthetic considerations dominated purchasing decisions. This consumer realignment reflects broader cultural shifts toward body autonomy, wellness prioritization, and rejection of historically uncomfortable fashion conventions.

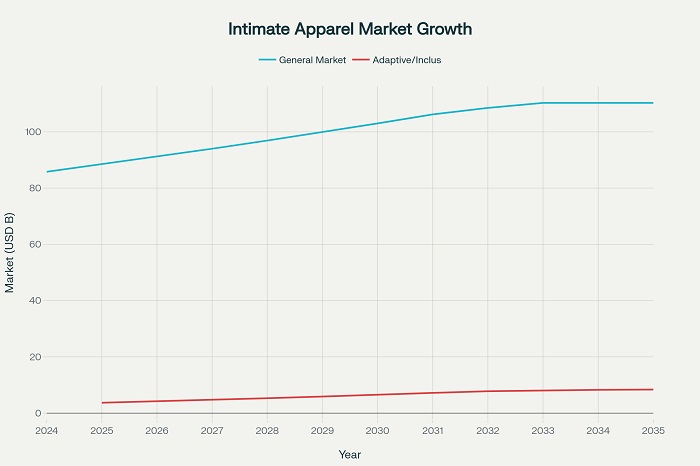

This preference evolution directly drives intimate apparel market expansion, with the global market valued at USD 85.8 billion in 2024 and projected to reach USD 110.3 billion by 2033. More significantly, segments emphasizing technological comfort innovations—wireless bra designs, moisture-wicking fabric systems, seamless construction, and adaptive fit technologies—demonstrate accelerated growth rates substantially exceeding traditional intimate wear categories. The adaptive shapewear segment alone illustrates this trend, expanding from USD 3.7 billion in 2025 to an anticipated USD 8.4 billion by 2035, representing a compound annual growth rate of 8.5 percent.

This market visualization reveals the substantial growth opportunities within advanced stretch fabric segments, with adaptive wear and technology-enhanced intimate apparel demonstrating expansion rates substantially exceeding general market averages.

Technological Adoption and Market Traction

Market introduction of advanced stretch technologies within intimate apparel has generated enthusiastic consumer response, validating manufacturers’ substantial R&D investments. Over forty-two billion units incorporating moisture-wicking, antibacterial, and stretchable fabrics shipped in 2024 alone, reflecting unprecedented demand for technologically sophisticated intimate wear. This volume milestone demonstrates that stretch innovation considerations extend far beyond luxury positioning—mainstream consumers actively seek and readily purchase intimates incorporating advanced elastomeric systems.

The rise of seamless and no-line intimate apparel particularly exemplifies technology-driven market growth. These products, which would be impossible without advanced multidirectional stretch capabilities, recorded twenty-two percent unit sales growth annually. Similarly, the integration of body-mapping principles and localized elastomeric optimization has enabled shapewear redesign, shifting from uncomfortable compression-centric approaches toward “body-sculpting without compression,” resulting in a fifteen percent increase in repeat purchase rates and substantially elevated customer satisfaction metrics.

From Conventional to Next-Generation Solutions

The Evolution of Spandex Technology

Spandex’s introduction to intimate apparel markets in the early 1960s represented a transformative innovation, delivering unprecedented elasticity and comfort compared to rigid supportive materials. However, the intervening decades have revealed both spandex’s remarkable performance characteristics and its ecological limitations. Petroleum-derived, difficult to recycle when blended with other fibers, and requiring energy-intensive manufacturing processes, conventional spandex presents sustainability challenges that increasingly conflict with contemporary consumer values and corporate environmental commitments.

This technological tension—between proven performance and environmental responsibility—has motivated sustained innovation across the elastomeric fiber industry. Rather than accepting tradeoffs between comfort and sustainability, leading manufacturers pursue what might be termed “transcendence alternatives,” where ecological improvements emerge from enhanced technical capabilities. YULASTIC’s superior elastic recovery compared to conventional spandex exemplifies this approach: sustainability becomes the natural byproduct of superior fiber science rather than a compromise demanded by environmental considerations.

The trajectory from conventional spandex toward next-generation alternatives will likely remain gradual, reflecting both the established performance expectations consumers now possess and the substantial production infrastructure built around traditional elastomeric systems. However, market indicators suggest meaningful market share migration toward sustainable alternatives, particularly within premium intimate apparel segments where consumers willingly invest additional resources for environmentally responsible options.

Smart Textiles and Responsive Fabric Systems

The frontier of intimate apparel innovation extends beyond conventional elasticity toward responsive textile systems that actively adapt to environmental conditions or wearer physiology. Phase change materials, for instance, absorb thermal energy when skin temperature rises and release stored energy when ambient conditions cool, maintaining skin-surface temperatures within the narrow comfort band of ±4.5 degrees Celsius around baseline thirty-three degrees Celsius values. These microencapsulated PCMs integrate directly into intimate wear structures, delivering temperature regulation previously achievable only through layering or environmental climate control.

Similarly, research into shape memory polymers suggests future intimate apparel capabilities where garments automatically adjust fit parameters based on wearer movement patterns or environmental conditions. These polymers exhibit recoverable strains exceeding eight hundred percent while maintaining programmable shape memory, opening possibilities for intimate wear that literally conforms to individual body contours with unprecedented precision.

Conclusion: The Future of Second-Skin Comfort

The convergence of advanced elastomeric engineering, body-mapping design principles, sustainable fiber innovation, and responsive material systems is fundamentally reconceiving intimate apparel from passive garments into active comfort platforms. Modern stretch innovation delivers genuine second-skin comfort—garments that enhance rather than constrain, that anticipate rather than merely respond to wearer needs, that combine ecological responsibility with exceptional performance.

Contemporary intimate apparel consumers benefit from technological investments that would have seemed fantastical only decades ago: multidirectional elasticity that accommodates unrestricted movement, seamless construction eliminating irritation points, moisture-wicking systems maintaining dryness and freshness, and body-mapping precision calibrating every square centimeter of fabric to specific anatomical requirements. As sustainable elastomeric alternatives gain market traction and responsive textile technologies mature toward commercial viability, the intimate apparel industry will continue advancing toward garments that literally move with human bodies while supporting conscious, sustainable consumption.

The second-skin comfort revolution represents far more than incremental product improvement. It reflects fundamental recognition that intimate apparel profoundly influences daily well-being, body confidence, and overall quality of life. Through continued innovation in elastomeric engineering and textile science, manufacturers are transforming intimate wear into genuine performance wear—garments that empower wearers to move freely, feel confident, and embrace bodies without compromise.