The Transformation Powered by Eco Responsible Textile Materials

The apparel industry stands at an unprecedented crossroads. With textile production generating 1.2 billion tons of greenhouse gas emissions annually and consuming 1.5 trillion liters of water, the necessity for fundamental change has become undeniable. Within this environmental crisis exists a compelling opportunity—eco responsible textile materials are actively reshaping how the apparel industry manufactures products, drives innovation, and defines corporate responsibility. These sustainable fibers and low impact production methods represent far more than contemporary fashion trends; they embody an essential evolution in manufacturing philosophy, consumer choice, and organizational accountability.

Understanding Why Eco Responsible Textile Materials Matter

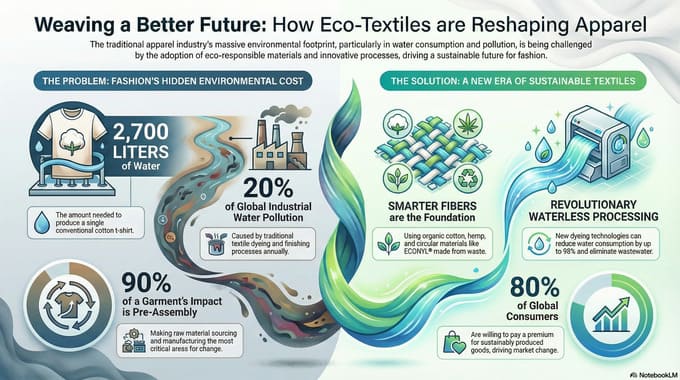

The fashion industry’s environmental footprint is staggering in scope and consequence. Producing a single cotton t-shirt requires approximately 2,700 liters of water—equivalent to human consumption over 2.5 years. A pair of jeans demands up to 10,000 liters. Beyond agricultural consumption, textile dyeing and finishing processes consume another half trillion gallons of freshwater annually, making the industry responsible for roughly 20 percent of global industrial water pollution. Simultaneously, apparel sector emissions reached 944 million tonnes in 2023, accounting for nearly 2 percent of total global emissions. This crisis context explains why eco responsible textile materials and sustainable fibers have transitioned from niche concerns into strategic imperatives.

What distinguishes eco responsible textile materials from conventional alternatives is their fundamental approach to environmental stewardship. Rather than perpetuating resource-intensive processes, eco conscious textiles utilize alternative fibers, closed-loop manufacturing systems, and waterless processing technologies. Research from the Glimpact study reveals that 90 percent of a garment’s environmental impact occurs before assembly, positioning raw material sourcing and manufacturing processes as critical intervention points. This finding underscores why transitioning to eco responsible textile materials represents the most strategically valuable sustainability action the apparel industry can undertake.

Sustainable Fibers: Natural and Innovative Solutions

Organic cotton epitomizes responsible apparel production practices. Grown without synthetic pesticides or fertilizers, organic cotton cultivation promotes biodiversity, reduces water pollution, and supports soil fertility through crop rotation systems. Major producing regions including India, China, and Turkey now dedicate substantial capacity to certified organic operations. Hemp represents perhaps the most resource-efficient natural fiber available, requiring minimal water, pesticides, and land while absorbing carbon dioxide rapidly. Hemp’s exceptional durability means garments last considerably longer, extending product lifecycles and reducing replacement demand—a critical sustainability advantage often overlooked.

Eco friendly materials increasingly extend beyond traditional natural fibers. Tencel, manufactured using closed-loop solvent recovery processes, recycles 99 percent of solvents while transforming viscose from chemically intensive into environmentally responsible fiber production. Bamboo lyocell employs similar closed-loop technology, producing naturally hypoallergenic, breathable fabric using significantly less water than traditional bamboo viscose. Recycled polyester and ECONYL® nylon represent circular innovations—ECONYL® transforms tire waste into textile fiber while reducing climate impact by 90 percent compared with petroleum-derived nylon.

Revolutionary Processing: Low Impact Textile Manufacturing

Even the most sustainable fibers require responsible processing. Traditional textile dyeing consumes enormous water quantities while releasing pollutants—a process generating substantial industry water consumption and chemical pollution. Waterless dyeing technologies inject color directly into molten plastic or utilize carbon dioxide-based solutions under pressure. We aRe SpinDye’s methodology achieves 75 percent water reduction, 90 percent chemical usage reduction, and 30 percent carbon reduction. COLOURizd’s technology surpasses this, achieving 98 percent water consumption reduction with zero wastewater and harmful discharge, alongside 73 percent carbon footprint reduction.

These processing innovations demonstrate how low impact textiles extend beyond fiber selection into manufacturing methodology. Zero liquid discharge systems address wastewater management—perhaps the textile industry’s most significant challenge. When dyeing and processing consume enormous water quantities while releasing pollutants, zero liquid discharge represents transformative innovation. By ensuring no water is wasted or released untreated, manufacturers fundamentally alter their environmental impact profile. Carbon dioxide-based dyeing technologies from companies like DyeCoo have achieved results adopted by global athletic brands, preserving millions of liters of water annually through straightforward process transformation.

Brand Responsibility and Transparent Supply Chains

Eco responsible textile materials represent merely one dimension of comprehensive sustainability. Responsible apparel production increasingly demands supply chain transparency and accountability. The European Union’s Corporate Sustainability Reporting Directive mandates that companies operating in EU markets report environmental and social impact using standardized methodology. This regulatory framework transforms transparency from voluntary commitment into compliance requirement, fundamentally altering competitive dynamics for responsible apparel producers.

Transparent supply chains empower consumers to align purchases with values while holding brands accountable. Research examining sustainability disclosures among major brands found that transparent, externally validated reporting significantly enhances brand credibility and establishes industry standards. Brands like Patagonia demonstrate this approach through Fair Trade Certified programs offering consumers visibility into purchase impacts. When companies openly share sourcing information, manufacturing practices, and end-of-life options, consumer confidence strengthens and market advantages accumulate for sustainability leaders.

Market Transformation and Consumer Demand

Contemporary consumer behavior validates the business case for eco conscious textiles. Approximately 80 percent of global consumers report willingness to pay premiums for sustainably produced goods, according to PwC’s 2024 Voice of the Consumer Survey. The secondhand apparel market, valued at USD 91.12 billion in 2022, continues accelerating as consumers recognize that extending garment lifecycles provides equivalent environmental benefits to material innovation. Research demonstrates that extending clothing lifespan by nine months reduces carbon, water, and waste footprints by 20 to 30 percent. Doubling usage frequency from 30 to 60 wears reduces greenhouse gas emissions footprints by nearly half.

This market reality creates powerful incentives for apparel brands to embrace eco friendly materials and responsible production. The circular fashion market, valued at USD 6.78 billion in 2024, projects growth to USD 18.42 billion by 2035. This accelerating investment validates that sustainable fibers and low impact production represent emerging market winners rather than niche segments. Brands positioning themselves as sustainability leaders gain competitive advantages through consumer preference, regulatory alignment, operational efficiency, and risk mitigation.

Regulatory Framework and Industry Compliance

Environmental regulation increasingly mandates eco responsible textile material adoption. The Clean Water Act and Clean Air Act require manufacturers to meet specific environmental standards. GOTS and OEKO-TEX certifications establish baseline expectations for eco conscious production. India’s Environment Protection Act mandates sustainable practice implementation in textile manufacturing. Extended Producer Responsibility frameworks require companies to manage products throughout entire lifecycles, incentivizing circular design thinking and end-of-life planning.

National action plans on climate change consolidate governmental efforts supporting sustainable textile transitions. India’s National Action Plan promotes energy efficiency, resource conservation, and waste management. The National Solar Mission fosters renewable-powered facilities. The National Mission for Enhanced Energy Efficiency encourages technology adoption reducing carbon footprints. These frameworks transform eco responsible textile material adoption from discretionary choice into strategic necessity for regulatory compliance and long-term operational viability.

The Future of Eco Responsible Textile Materials

Eco responsible textile materials have transcended aspirational positioning to become manufacturing reality. Technological solutions exist for sustainable fiber production, waterless processing, waste reduction, and circular design. Market demand accelerates as consumers, investors, and regulators prioritize environmental accountability. The question confronting apparel industry participants is not whether sustainable textiles will dominate future production but whether individual organizations will lead this transition or experience it as crisis.

Forward-thinking companies recognize eco conscious textiles not as compromises but as fundamental expressions of responsible production. This transformation has commenced, driven by environmental imperative, regulatory requirement, consumer demand, and technological feasibility. The convergence of these forces ensures continued momentum toward comprehensive industry transformation. The apparel industry’s future belongs to brands that embrace eco responsible textile materials, implement low impact production, maintain transparent supply chains, and demonstrate genuine commitment to environmental stewardship. Through these comprehensive approaches, the fashion industry can generate value while respecting environmental limits and community wellbeing.