The Shaw Institute, a nonprofit organization specializing in scientific research, has tested and certified CLEANR’s external microplastic filter for washing machines to be over 90% effective at capturing microplastics as small as 50 microns. CLEANR for Washing Machines is set to launch in the U.S. later this year, providing consumers with a practical tool to combat microplastic pollution.

Washing machines are the largest source of microplastic pollution, contributing to 35% of total emissions. Microplastics, defined as plastic particles smaller than 5 millimeters, have been linked to significant human health risks, including heart disease, digestive cancers, and reproductive disorders.

“The Shaw Institute is a global authority on plastic pollution and marine health, and we’re honored to have their validation of our technology,” said David Dillman, Co-Founder and Chief Technology Officer of CLEANR. “These results emphasize the impact of our filtration solution and its ability to help consumers tackle microplastic pollution. This third-party assessment marks a major milestone as we prepare to launch our product in the U.S. later this year.”

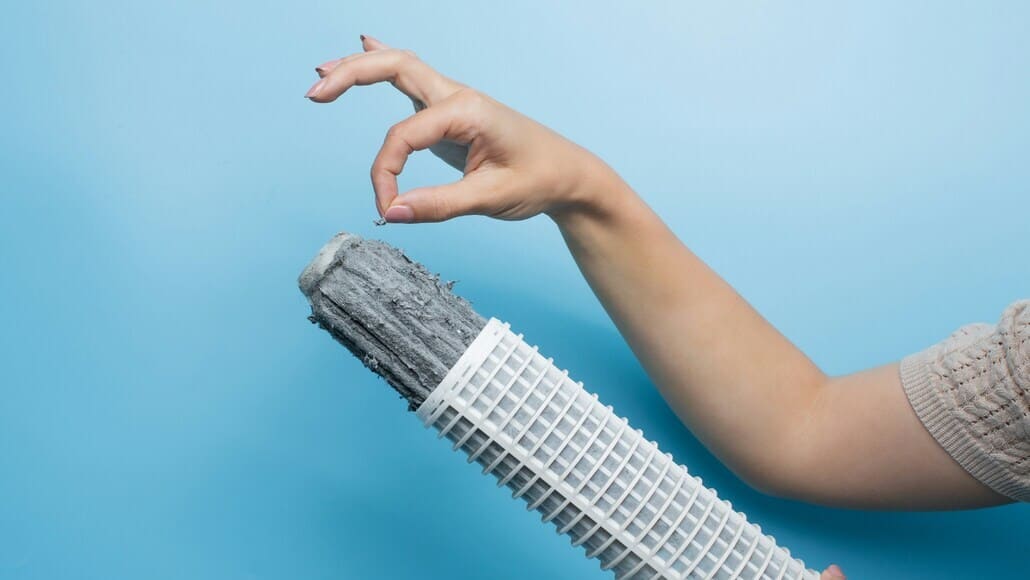

CLEANR’s innovative filtering technology, VORTX, stands out from conventional microplastic solutions for washing machines. Inspired by the efficient gill structures of manta rays and basking sharks, VORTX uses vortex currents to suspend and isolate microplastic particles rather than forcing them against a filtering surface. These particles are then collected in the CLEANR Pod, a microplastic capture unit, ensuring they are properly disposed of.

90%+ Microplastic Removal Confirmed by Testing

The Shaw Institute rigorously tested CLEANR for Washing Machines by running a mixture of tap water and plastic flock fibers (10 microns in diameter and 300 microns in length) through the filter under simulated real-world laundry conditions. Tests conducted in January and February revealed impressive microplastic removal rates of 90%, 97%, and 98%, confirming the filter’s remarkable efficiency.

“We are proud to partner with CLEANR on this important initiative as part of our new program validating technological innovations aimed at reducing plastic pollution,” said Dr. Charlie Rolsky, Executive Director of the Shaw Institute. “Microplastics pose a significant threat to human and environmental health, and developing solutions to mitigate exposure is critical.”

CLEANR’s cutting-edge technology offers a promising approach to reducing the environmental and health hazards associated with microplastic pollution, making a significant step forward in combating this global issue.