The Hong Kong Research Institute of Textiles and Apparel (HKRITA) and Seiko Epson Corporation have made significant strides in developing a new regenerated cellulose fiber with a silk-like sheen from waste cotton fabric through an innovative production process.

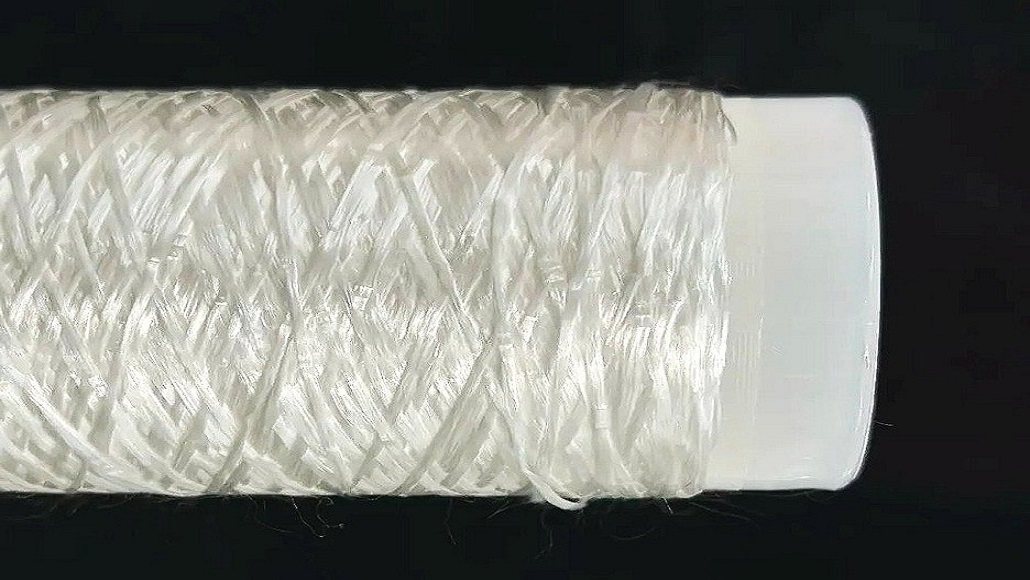

This new method combines Epson’s proprietary Dry Fibre Technology for textile regeneration with HKRITA’s fiber dissolving technology. The process involves converting discarded cotton fabrics into a powder-like form, dissolving the cotton in a solvent, and extruding it through a nozzle into a coagulation bath, where it solidifies and is spun into new fibers.

The resulting regenerated fiber boasts the strength of virgin cotton and is targeted for high-end applications such as scarves, ties, and suit linings. Additionally, since the short fibers generated during the production of the regenerated fiber can be utilized rather than discarded, this process has the potential to enhance overall clothing recycling rates.

“As an applied research center, HKRITA is dedicated to solving real-world problems and enhancing current practices and products,” stated HKRITA CEO Jake Koh. “We are excited to partner with Epson to recycle fibers and transform them into high-quality yarns. This cross-industrial collaboration is not only reimagining materials but also redefining the future of sustainable production.”

“We are extremely pleased with the results that this joint development project has yielded,” added Epson executive officer Satoshi Hosono. “The selective application of this new wet process and our previously developed dry process should allow for the regeneration of fibers from all waste cotton fabrics while minimizing environmental impact.”