The Golisano Institute for Sustainability (GIS) at the Rochester Institute of Technology (RIT) is at the forefront of innovation in textile recycling, developing a fully automated system designed to identify, sort, and disassemble used garments quickly and efficiently. This initiative seeks to tackle the pressing issue of global textile waste.

In the United States alone, over 11 million tons of textiles are sent to landfills each year. Much of this waste comprises garments that are complicated to recycle due to mixed materials, components like zippers and buttons, and inconsistencies in garment composition.

Led by program manager Mark Walluk, the RIT team includes engineers Ryan Parsons, Nick Spears, Sri Priya Das, Ronald Holding, and Christopher Piggot, along with associate research professor Abu Islam. They have focused on developing an automated system that identifies and removes non-recyclable items to facilitate higher-value material recovery.

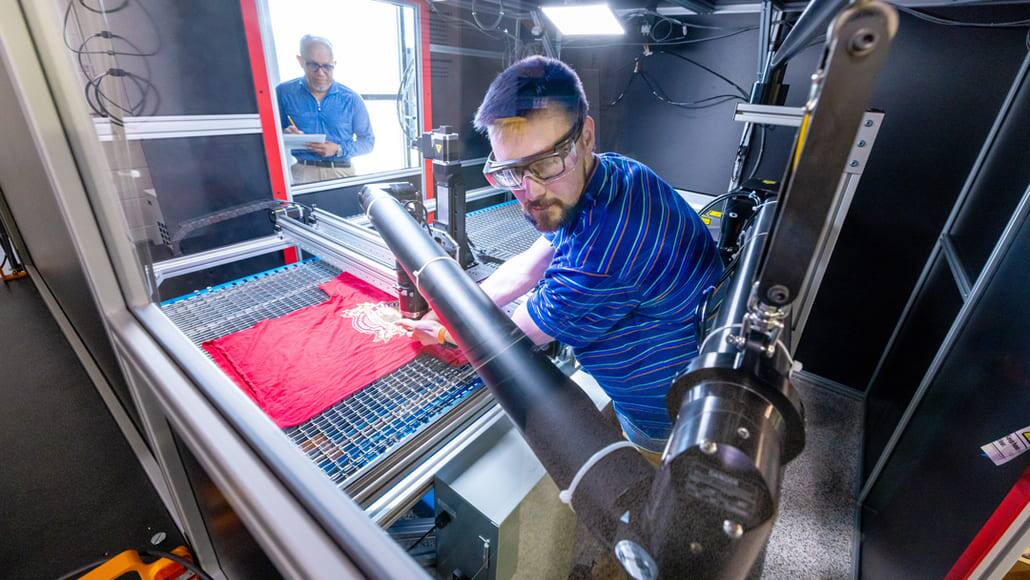

The process kicks off at a conveyor-fed imaging station, where specialized cameras create a high-resolution, multi-dimensional map of each garment, allowing for detailed fiber composition analysis. The system leverages artificial intelligence and machine vision to identify and eliminate non-recyclable elements.

“In traditional manufacturing, these automations have been used for decades and it’s predictable,” said Islam. “You know what part is coming next and exactly where it goes. In used clothing, every item is different. That unpredictability means the system must make on-the-spot decisions.”

To tackle this challenge, Islam and Das devised vision-guided algorithms that detect features like logos and cuffs while interpreting infrared reflections to determine fiber types. The resulting data guides a robotic laser-cutting system that precisely removes non-recyclable features without damaging usable material.

Walluk commented on the broader impact of the technology: “It’s not going to solve the world’s textile waste problem, but it’s a step toward a more circular economy. Today, recyclers prefer post-industrial fabrics because of their predictable material properties. We’re working to advance beyond that step by transforming post-consumer clothing into high-quality, reliable feedstock also.”

Key collaborators on the project include Ambercycle, a California-based company specializing in polyester recycling, and Goodwill of the Finger Lakes, which provided garments for testing and insights into the resale market. Nike contributed industry guidance during the project’s initial stages.

The project, funded by a grant of nearly $1.3 million from the REMADE Institute, began in 2023. The team showcased their work at a global REMADE conference in Washington, D.C., in April.

“Textile recycling is a critical global challenge, and we’re proud to collaborate with industry leaders to drive meaningful solutions,” said Nabil Nasr, Director of GIS and CEO of the REMADE Institute. “This effort not only creates significant environmental impact but also represents a major area of growth and innovation for us at GIS.”

Though still in the pilot phase, the innovative technology has garnered interest from recyclers in the U.S., Europe, South Asia, and Latin America. The team anticipates transitioning the system to its partners for ongoing testing and potential deployment later this year.