The global textile industry stands at the intersection of tradition and innovation, with textile fiber types serving as the fundamental building blocks of every garment and fabric product we encounter. From the humble cotton shirt to advanced performance wear, understanding the characteristics and applications of different textile fibers has become essential for manufacturers, designers, and conscious consumers alike. The choice between natural fibers, synthetic alternatives, and regenerated materials significantly influences fabric performance, environmental impact, and end-user satisfaction.

Textile fibers represent the raw materials that define the functionality, comfort, and longevity of finished products. Whether you’re developing sustainable fashion lines, manufacturing industrial textiles, or simply seeking to understand what goes into your everyday clothing, a comprehensive knowledge of fiber properties and applications becomes invaluable. This guide explores the complete spectrum of textile fiber types, their inherent properties, practical benefits, and diverse industrial applications that shape modern textile production.

Understanding Textile Fiber Classification

The Foundation of Modern Textiles

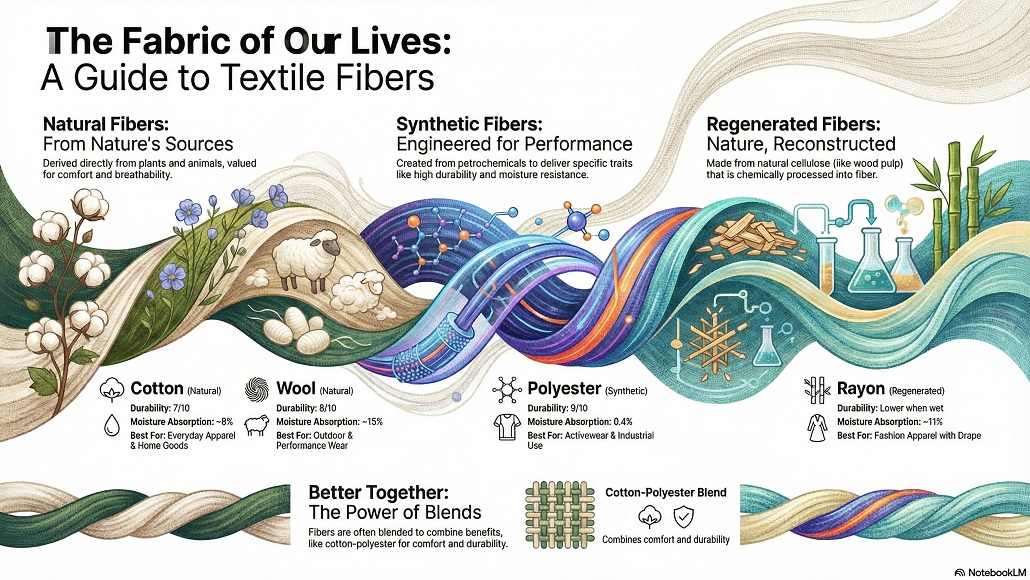

Textile fibers are classified into three primary categories that represent different sourcing and processing methodologies. Natural fibers emerge directly from plants, animals, and mineral sources, requiring minimal processing before becoming usable textile materials. Synthetic fibers, conversely, result from petrochemical derivatives through complex polymerization processes, engineered to deliver specific performance characteristics. Regenerated fibers occupy a middle ground, derived from natural cellulose but reconstructed through chemical processing to achieve enhanced properties and consistent quality standards.

This classification system emerged from industrial necessity, as manufacturers sought materials that could meet increasingly diverse performance requirements. Each category presents distinct advantages and limitations that make certain fibers preferable for specific applications. Understanding these distinctions allows industry professionals to make informed decisions when selecting materials for particular production needs.

Natural Fibers: Heritage and Performance

Cotton: The Industry Standard

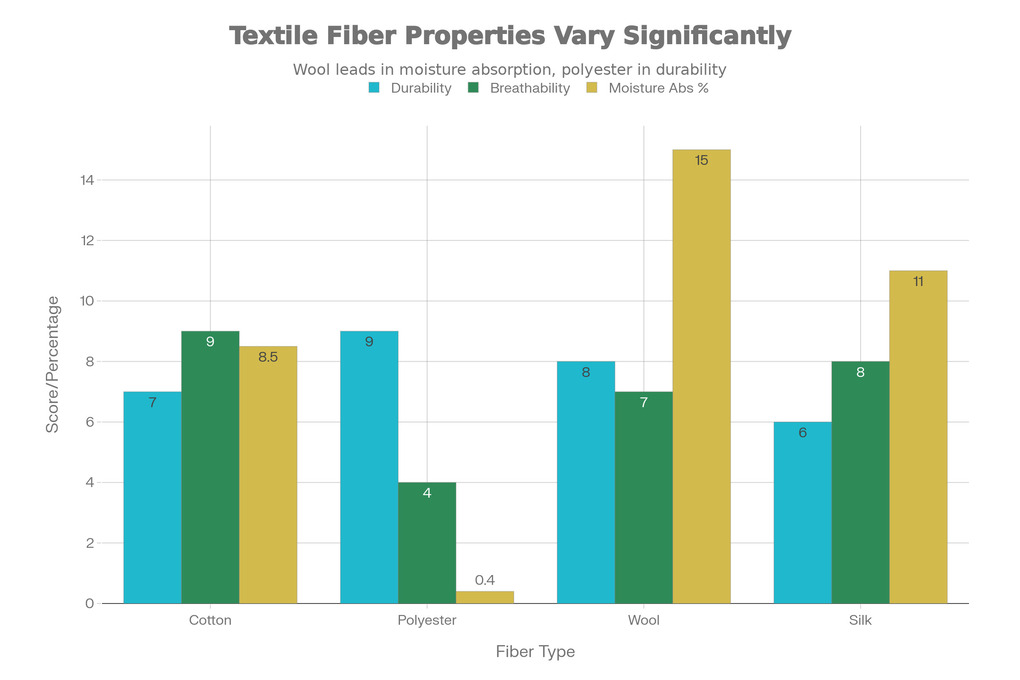

Cotton fabric remains the most widely cultivated and utilized natural fiber globally, accounting for approximately thirty percent of world fiber consumption. The unique properties of cotton stem from its cellulose composition, which creates exceptional breathability and moisture-wicking capabilities. Cotton’s natural absorbency reaches approximately eight percent, making it ideal for everyday apparel, particularly in warm climates where heat dissipation proves critical.

The versatility of cotton extends across numerous applications. Beyond conventional apparel production, cotton serves the home textile sector through bed linens, towels, and upholstery. Medical textile applications benefit significantly from cotton’s hypoallergenic properties and biocompatibility. Industrial applications utilize cotton in canvas materials, protective equipment, and specialized technical textiles. The durability rating of quality cotton fabric typically reaches seven out of ten, with lifespan influenced heavily by weave construction and finishing processes.

Cotton production sustainability has become increasingly important to conscious consumers and environmentally responsible manufacturers. Organic cotton cultivation eliminates synthetic pesticides and fertilizers, though traditional cotton farming involves considerable water consumption and chemical inputs. The textile industry continues developing more sustainable cotton production methodologies to address environmental concerns while maintaining quality standards.

Wool: Nature’s Temperature Regulator

Wool fiber possesses remarkable thermodynamic properties that distinguish it from most other natural fibers. The protein structure of wool allows it to absorb moisture without feeling damp, regulating body temperature through sophisticated moisture management. This characteristic makes wool exceptionally valuable for performance apparel, particularly in outdoor and sports applications where temperature fluctuations demand material responsiveness.

The crimp structure inherent in wool fibers creates natural elasticity and resilience, contributing to excellent durability ratings of approximately eight out of ten. Wool’s ability to recover from compression ensures that garments maintain their shape through extended wear cycles. The fiber’s moisture absorption capacity reaches approximately fifteen percent, allowing wool to retain significant moisture without compromising thermal insulation properties.

Beyond apparel, wool finds substantial application in home furnishings, where its flame-resistant properties and acoustic insulation qualities prove valuable. Industrial applications include blankets, felt products, and specialized thermal textiles. Merino wool, a particular wool variety, has gained prominence in performance activewear due to its refined fiber diameter and superior softness compared to conventional wool varieties.

Silk: Luxury and Sophistication

Silk represents the most luxurious natural fiber, produced from the cocoons of mulberry silkworms through complex sericulture processes. The protein structure of silk creates unparalleled smoothness and a distinctive lustrous appearance that distinguishes silk products from all other textile materials. With a durability rating of six out of ten, silk requires careful handling but delivers unmatched aesthetic qualities and exceptional comfort against human skin.

Silk’s moisture absorption reaches approximately eleven percent, creating optimal conditions for temperature regulation in luxury apparel. The fiber’s natural protein composition provides inherent UV protection, making silk valuable for sun-protective clothing applications. Beyond fashion, silk serves medical and pharmaceutical industries through biocompatible applications and specialized healthcare textiles.

The production methodology profoundly influences silk’s environmental footprint. Traditional silk production involves sericulture practices that require substantial agricultural resources. Peace silk represents an alternative approach where cocoons are harvested after silk moths emerge naturally, eliminating pupal mortality but increasing production costs and complexity.

Synthetic Fibers: Engineering Excellence

Polyester: Versatility and Performance

Polyester stands as the most extensively utilized synthetic fiber globally, commanding approximately twenty-nine percent of world fiber consumption. The polymer structure of polyester creates exceptional durability, with ratings reaching nine out of ten, making polyester ideal for applications demanding longevity and resistance to environmental stressors. This synthetic fiber demonstrates remarkable resistance to moisture, chemicals, and degradation, ensuring extended product lifespan.

The hydrophobic nature of polyester presents both advantages and challenges. While this property creates exceptional water resistance beneficial for protective wear and outdoor textiles, it simultaneously compromises breathability, with ratings reaching only four out of ten. Polyester’s low moisture absorption of 0.4 percent contributes to rapid drying characteristics, making it valuable for activewear and performance applications where moisture management proves critical.

Polyester production involves complex polymerization processes that transform petroleum-derived monomers into long polymer chains. Mechanical strength and dimensional stability characterize polyester fabrics, allowing for precise manufacturing consistency. Contemporary polyester production increasingly incorporates recycled polyester derived from post-consumer plastic bottles, advancing sustainable manufacturing practices and reducing environmental impact.

Nylon: Strength and Innovation

Nylon fibers exhibit exceptional mechanical strength combined with remarkable elasticity, properties that positioned nylon as revolutionary when first introduced to textile markets. The polymer chains inherent in nylon create superb abrasion resistance and resilience, making nylon ideal for high-stress applications including hosiery, swimwear, and performance activewear. Nylon’s durability substantially exceeds most alternative synthetic fibers.

The versatility of nylon extends into technical textile applications, where its strength-to-weight ratio proves advantageous. Carpet manufacturing represents a major nylon application, where fiber resilience and traffic resistance remain paramount. Geotextiles and industrial applications leverage nylon’s chemical resistance and mechanical properties.

Acrylic: Wool Simulation and Accessibility

Acrylic fibers were engineered as wool substitutes, targeting the luxury wool market while maintaining significantly lower production costs. The polymer structure creates fibers with comparable warmth and comfort characteristics to natural wool, though with distinctly different chemical properties. Acrylic provides excellent color retention and resistance to environmental degradation, making vibrant colors resistant to fading.

The affordability of acrylic combined with its wool-like properties democratized access to warm, comfortable knitwear across broader consumer demographics. Applications include sweaters, blankets, and home textiles where cost-effectiveness and ease of care prove important consumer considerations.

Regenerated Fibers: Bridging Natural and Synthetic

Rayon: Traditional Regeneration

Rayon represents the earliest successfully commercialized regenerated fiber, produced through the viscose process that dissolves cellulose in chemical solvents before re-precipitating it into fiber form. This methodology preserves the natural properties of cellulose while enabling manufacturing control and consistency. Rayon demonstrates breathability comparable to cotton while offering enhanced drape and aesthetic qualities appreciated in fashion applications.

The moisture absorption of rayon reaches approximately eleven percent, providing comfortable wear characteristics in warm climates. Durability considerations require careful handling, as rayon strength diminishes when wet, necessitating appropriate care protocols. Modern viscose production employs closed-loop manufacturing systems that capture and recycle chemical solvents, substantially reducing environmental impact compared to historical processes.

Lyocell: Sustainable Innovation

Lyocell fibers emerge from a more sophisticated regeneration process using N-methylmorpholine-N-oxide (NMMO) as a non-toxic solvent, demonstrating superior environmental credentials compared to traditional viscose processes. This solvent recovery system achieves recycling rates exceeding ninety-nine percent, virtually eliminating chemical discharge to aqueous environments. Lyocell maintains the natural aesthetic and comfort characteristics of cellulose while delivering enhanced durability through superior fiber structure.

The development of lyocell technology exemplifies how materials science advances can simultaneously enhance performance and environmental responsibility. Major textile manufacturers have increasingly adopted lyocell production as consumer demand for sustainable textiles continues expanding.

Modal: Refined Regeneration

Modal fibers result from specialized viscose processes employing high wet-modulus techniques that enhance fiber strength and dimensional stability. The resulting fibers exhibit superior shrinkage resistance and durability compared to conventional rayon, making modal preferable for demanding applications. Modal’s inherent moisture absorption and breathability characteristics align closely with cotton properties, positioning modal as cotton substitute in numerous applications.

The softness of modal fibers appeals strongly to luxury apparel markets, where silky handle and elevated aesthetic qualities command premium pricing. Intimate apparel and high-end casual wear increasingly incorporate modal fibers as manufacturers pursue sustainable luxury positioning.

Comparative Properties and Selection Criteria

The selection of appropriate textile fiber types depends on comprehensive evaluation of application requirements, performance parameters, and environmental considerations. Cotton fabric excels for breathable everyday wear but demands greater care and resources than synthetic alternatives. Polyester delivers exceptional durability and color retention, though with compromised breathability in high-performance applications. Wool provides unmatched thermal regulation for temperature-variable environments. Silk offers incomparable luxury but requires delicate handling. Regenerated fibers bridge sustainability aspirations with practical performance requirements.

Industrial professionals increasingly adopt fiber blending strategies that combine complementary properties from multiple fiber types. Cotton-polyester blends balance natural fiber comfort with synthetic durability. Wool-acrylic combinations provide affordability while maintaining warmth characteristics. These hybrid approaches enable manufacturers to optimize performance across competing requirements while managing production costs.

Industrial Applications and Market Dynamics

Apparel Manufacturing

The apparel sector represents the primary textile market, consuming approximately sixty-five percent of global fiber production. Natural fibers dominate premium and everyday casual wear segments, where comfort and aesthetic qualities prove decisive. Synthetic fibers command performance and activewear markets, where durability and moisture management supersede comfort considerations. Regenerated fibers increasingly penetrate fashion markets as consumers develop greater environmental consciousness.

Home Textiles and Furnishings

Home textile applications span bedding, towels, curtains, and upholstery, each segment demanding specific fiber characteristics. Cotton dominates the bedding sector through its comfort properties and established consumer preferences. Wool finds application in premium blankets and area rugs where thermal and acoustic properties prove valuable. Synthetic fibers increasingly penetrate home textiles through stain resistance and ease of care advantages.

Technical and Industrial Textiles

The technical textile sector encompasses geotextiles, automotive textiles, medical textiles, and protective equipment applications where functionality supersedes aesthetic considerations. Synthetic fibers dominate this segment due to superior durability, chemical resistance, and dimensional stability. Specialized high-performance fibers including aramids and polyamides address extreme performance requirements. This segment experiences robust growth as industrial applications expand across infrastructure, transportation, and healthcare sectors.

Sustainability Considerations and Future Directions

Contemporary textile fiber selection increasingly incorporates environmental impact assessment alongside performance evaluation. Natural fiber production, while renewable, demands substantial water resources and agricultural inputs. Synthetic fiber production relies on petroleum derivatives, raising climate change concerns despite superior recycling potential. Regenerated fibers theoretically balance renewable sourcing with manufacturing efficiency, though practical environmental outcomes depend heavily on production methodology and solvent recovery implementation.

The textile industry continues developing innovative fiber technologies addressing sustainability imperatives. Mycelium-based fibers derived from fungal cultivation, lab-grown spider silk proteins, and advanced cellulose fibers from agricultural waste represent emerging alternatives. These innovations demonstrate commitment to developing textile fiber types that simultaneously deliver performance excellence and environmental responsibility.

Conclusion

Understanding textile fiber types and their respective properties, benefits, and applications empowers informed decision-making throughout the textile value chain. Whether prioritizing comfort, durability, sustainability, or cost-effectiveness, comprehensive knowledge of available fiber options enables optimization of products meeting specific market requirements and consumer expectations. As the textile industry continues evolving toward sustainability and performance excellence, expertise in fiber characteristics and applications remains increasingly valuable for manufacturers, designers, and industry professionals. The future of textiles will undoubtedly feature greater integration of traditional fiber knowledge with innovative material sciences, creating possibilities currently beyond our imagination.