The fashion industry stands at the threshold of a fundamental transformation as small quantity sourcing in fashion emerges as a strategic imperative that extends far beyond cost optimization to encompass agility, creativity, and sustainability. This evolution represents a decisive shift away from traditional mass production models toward more responsive, flexible manufacturing approaches that enable brands to test markets, reduce risks, and respond rapidly to changing consumer preferences. Capsule collections have become the catalyst for this transformation, demonstrating how small quantity sourcing can drive innovation while supporting sustainable practices that align with contemporary consumer values and regulatory requirements.

The Strategic Foundation of Small Quantity Sourcing

The emergence of small quantity sourcing in fashion reflects fundamental changes in market dynamics, consumer behavior, and competitive requirements that have rendered traditional high-volume manufacturing models less effective and more risky. Fashion companies are discovering that the ability to produce smaller batches with greater frequency provides competitive advantages that justify potentially higher per-unit costs while delivering superior market responsiveness and risk management.

Consumer behavior patterns have shifted dramatically toward demand for exclusivity, personalization, and sustainable consumption that favors limited-edition releases over mass-market availability. Modern consumers increasingly value products that feel unique and special, creating market opportunities for brands that can offer distinctive, limited-availability items through small quantity sourcing approaches.

Market volatility and trend acceleration have made large production commitments increasingly risky, as fashion cycles compress and consumer preferences become more unpredictable. Small quantity sourcing provides the flexibility to test market response before committing to larger production volumes, reducing the financial exposure associated with trend miscalculations or market shifts.

Digital commerce platforms and social media marketing have democratized access to consumers, enabling smaller brands and niche products to reach targeted audiences effectively without requiring massive production volumes to achieve economies of scale in marketing and distribution. This technological evolution has made small quantity sourcing commercially viable for a broader range of companies and product categories.

Sustainability consciousness among consumers and regulatory bodies has created market pressure for reduced overproduction and waste generation, making small quantity sourcing an environmental necessity rather than just a strategic option. Brands are discovering that consumers will pay premium prices for products that demonstrate genuine environmental responsibility through thoughtful production practices.

The rise of influencer marketing and social media showcasing has created new demand patterns where products can achieve viral success rapidly, requiring production systems that can scale quickly from small initial quantities to larger volumes based on market response. Small quantity sourcing provides the foundation for this type of responsive scaling.

Capsule Collections as Market Innovation

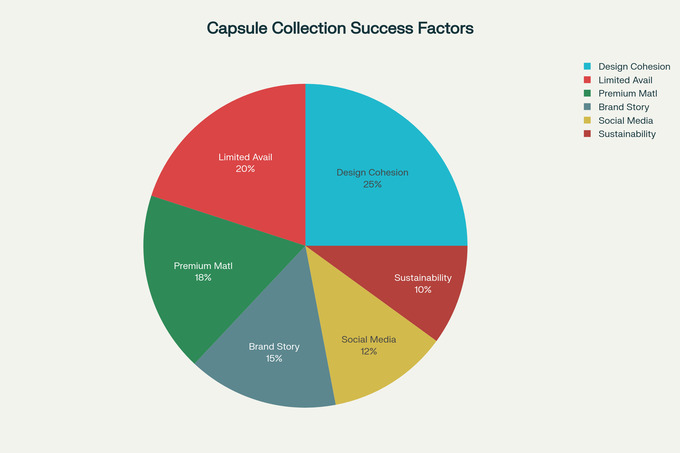

Capsule collections represent a sophisticated approach to fashion merchandising that leverages small quantity sourcing to create comprehensive style ecosystems from carefully curated, limited-edition pieces. These collections demonstrate how strategic product development can maximize market impact while minimizing inventory risk and production complexity.

The concept of capsule collections originated from the principle that fewer, higher-quality pieces that coordinate seamlessly can provide greater styling versatility than larger collections of disparate items. This approach appeals to contemporary consumers who value minimalist aesthetics, functional design, and investment purchasing over fast fashion consumption patterns.

Successful capsule collections require intensive design development and market research to ensure that each piece serves multiple styling functions while maintaining cohesive aesthetic appeal. This design intensity creates higher perceived value that can command premium pricing, offsetting the higher per-unit costs associated with small quantity sourcing.

The exclusivity factor inherent in capsule collections creates urgency and desirability that drives faster sales velocity and higher full-price sell-through rates compared to traditional seasonal collections. This market dynamic enables brands to maintain profitability despite higher production costs while building customer loyalty and brand equity.

Limited production runs associated with capsule collections enable brands to experiment with innovative materials, construction techniques, and design concepts that might be too risky for large-scale production. This experimental capability can lead to breakthrough innovations that differentiate brands in competitive markets.

The storytelling opportunities created by capsule collections enable brands to communicate their values, craftsmanship, and design philosophy more effectively than traditional product launches. Each capsule can represent a complete narrative that resonates with target consumers while building brand identity and emotional connection.

Manufacturing Agility and Supplier Relationships

The implementation of small quantity sourcing strategies requires fundamental changes in supplier relationships, manufacturing processes, and production planning that extend far beyond simply reducing order quantities. Success depends on developing manufacturing partnerships that prioritize flexibility, quality, and responsiveness over pure cost optimization.

Supplier selection criteria for small quantity sourcing must emphasize flexibility, quality consistency, and collaborative problem-solving capability rather than just cost competitiveness and production capacity. Manufacturers that can accommodate frequent style changes, variable production volumes, and shorter lead times become strategic partners rather than transactional suppliers.

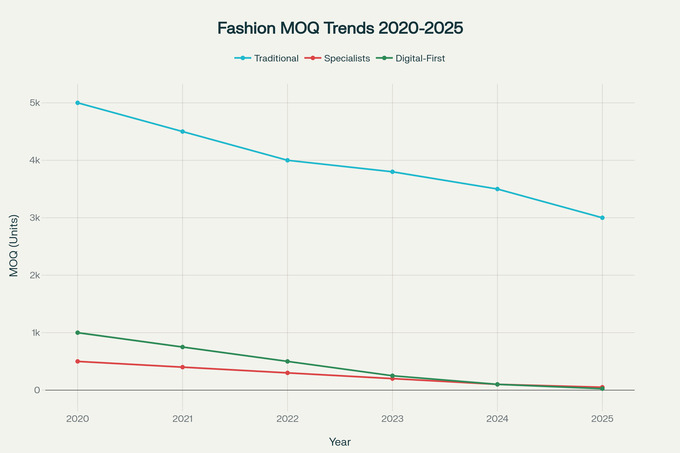

Minimum Order Quantity negotiations represent a critical success factor for small quantity sourcing implementations. Many traditional textile manufacturers prefer large orders to maximize efficiency and profitability, requiring fashion companies to identify and develop relationships with suppliers who can accommodate smaller production runs profitably.

The geographic proximity of suppliers becomes more important for small quantity sourcing due to the need for frequent communication, rapid sampling, and quick response to design modifications. Near-sourcing strategies that prioritize regional manufacturing partners can provide the responsiveness and collaboration required for effective small quantity production.

Digital communication and collaboration tools become essential for managing small quantity sourcing relationships effectively, enabling real-time communication about design specifications, production progress, and quality issues. These technological capabilities reduce the coordination complexity associated with managing multiple small orders across different suppliers.

Quality control systems must be adapted for small quantity production to ensure consistency across limited production runs while maintaining cost efficiency. This may require more intensive per-unit inspection and testing compared to large-volume production where statistical sampling methods can be more effective.

Inventory management and forecasting become more complex with small quantity sourcing due to the increased number of SKUs and shorter production cycles. Companies must develop sophisticated demand planning and inventory optimization systems that can handle the complexity of multiple small orders with varying lead times and delivery schedules.

Technology Integration and Digital Manufacturing

The success of small quantity sourcing strategies depends heavily on leveraging advanced manufacturing technologies and digital systems that enable efficient, high-quality production at smaller scales. These technological capabilities are essential for overcoming the traditional economies of scale that have favored large-volume manufacturing.

Digital sampling and virtual prototyping technologies reduce the time and cost associated with product development for small quantity production by eliminating multiple physical sampling rounds. These systems enable designers to visualize and modify designs digitally before committing to physical production, reducing development costs and accelerating time-to-market.

On-demand manufacturing systems using digital printing, automated cutting, and flexible assembly processes can produce small quantities efficiently without the setup costs and minimum volumes required by traditional manufacturing methods. These systems enable profitable production of individual pieces or very small batches while maintaining quality standards.

3D knitting and seamless manufacturing technologies enable zero-waste production of small quantities by creating finished garments without cutting and sewing operations that generate fabric waste. These advanced manufacturing methods support sustainability objectives while enabling efficient small-batch production.

Artificial intelligence and machine learning systems can optimize production planning, inventory management, and demand forecasting for small quantity sourcing by analyzing multiple data sources and identifying patterns that inform decision-making. These analytical capabilities become increasingly valuable as the complexity of managing multiple small orders increases.

Blockchain and traceability systems provide transparency and authenticity verification that can add value to small quantity products by enabling consumers to verify the provenance and production methods of limited-edition items. This transparency can justify premium pricing while supporting sustainability and authenticity claims.

Cloud-based production management systems enable real-time coordination between brands and manufacturers while providing visibility into production progress, quality metrics, and delivery schedules. These systems are essential for managing the complexity of multiple concurrent small quantity orders across different suppliers.

Sustainability and Environmental Impact

Small quantity sourcing in fashion provides substantial environmental benefits by reducing overproduction, minimizing waste, and enabling more responsible resource utilization. These sustainability advantages align with consumer values and regulatory requirements while supporting long-term business viability.

Overproduction reduction represents one of the most significant environmental benefits of small quantity sourcing, as fashion companies can avoid producing excess inventory that ultimately requires disposal or deep discounting that undermines brand value. The fashion industry generates billions of excess garments annually, making overproduction reduction a critical environmental priority.

Waste minimization throughout the production process becomes more feasible with small quantity sourcing because manufacturers can optimize material utilization more precisely for specific order quantities. Advanced cutting optimization and zero-waste design techniques become economically viable when applied to smaller production runs.

The ability to use premium sustainable materials becomes more economically feasible with small quantity sourcing because the total material cost for limited production runs can be managed even when per-unit material costs are higher. This enables brands to incorporate organic cotton, recycled fibers, and innovative sustainable materials without prohibitive total costs.

Local and regional sourcing becomes more practical with small quantity production because the reduced transportation requirements make shorter supply chains economically viable. This geographic optimization reduces carbon emissions while supporting local manufacturing economies and reducing supply chain complexity.

End-of-life planning and circular economy integration become more manageable with small quantity sourcing because brands can implement take-back programs, recycling initiatives, and material recovery systems more effectively when dealing with limited product quantities and known customer bases.

Consumer education and engagement around sustainability become more effective with small quantity products because brands can communicate detailed information about materials, production methods, and environmental impact for each limited collection. This transparency supports informed consumer decision-making while building brand credibility around sustainability claims.

Market Dynamics and Consumer Response

The market reception of small quantity sourcing strategies reveals important insights about contemporary consumer behavior, value perception, and purchasing patterns that inform strategic decision-making for fashion companies considering this approach.

Premium pricing acceptance has increased among consumers who recognize the value proposition of small quantity products, including higher quality, exclusivity, sustainability, and innovative design. This pricing tolerance enables brands to maintain profitability despite higher per-unit production costs associated with small quantity sourcing.

Customer loyalty and engagement tend to be higher for brands that successfully implement small quantity sourcing strategies because consumers develop stronger emotional connections to products that feel special and exclusive. This loyalty translates into repeat purchases, word-of-mouth marketing, and brand advocacy that supports long-term business growth.

Social media amplification of small quantity products can create viral marketing effects where limited availability drives increased consumer interest and social sharing. This organic marketing support can substantially reduce customer acquisition costs while building brand awareness and desirability.

The collector mentality among consumers creates ongoing demand for sequential small quantity releases, enabling brands to build sustainable business models based on regular capsule collections rather than traditional seasonal launches. This approach can provide more consistent revenue streams while maintaining consumer engagement throughout the year.

Market segmentation opportunities emerge from small quantity sourcing capabilities, enabling brands to serve niche markets and specialized consumer preferences that cannot be addressed profitably through mass production approaches. This market precision can create competitive advantages and reduce direct competition with larger brands.

Financial Models and Economic Viability

The economic dynamics of small quantity sourcing require sophisticated financial analysis that considers total cost of ownership, risk management, and long-term value creation rather than simple per-unit cost comparisons with mass production alternatives.

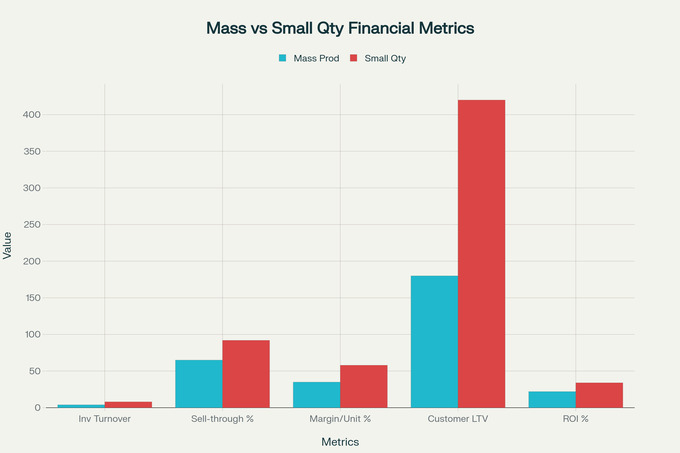

Unit cost premiums associated with small quantity sourcing can be substantial compared to large-volume production, but these higher costs must be evaluated against the reduced inventory risk, faster inventory turnover, and higher sell-through rates that small quantity strategies typically achieve. The overall financial impact often favors small quantity approaches despite higher production costs.

Inventory carrying cost reductions represent significant economic benefits of small quantity sourcing because brands can minimize working capital tied up in unsold inventory while reducing storage, insurance, and obsolescence costs. These savings can offset higher per-unit production costs while improving cash flow and financial flexibility.

Market testing and risk reduction benefits provide economic value that is difficult to quantify but can be substantial when considering the cost of failed product launches and unsold inventory. Small quantity sourcing enables brands to test market response before committing significant resources to large production runs.

Cash flow optimization becomes possible with small quantity sourcing because production investments can be spread over time and aligned more closely with actual sales, reducing the working capital requirements and financial risk associated with large upfront inventory investments.

Pricing flexibility increases with small quantity sourcing because brands can adjust pricing strategies based on market response without being constrained by large inventory positions that require specific margin targets to achieve profitability. This pricing agility can optimize revenue while responding to competitive dynamics.

Return on investment calculations for small quantity sourcing must consider the strategic value of brand building, customer relationship development, and market learning that these approaches provide in addition to direct financial returns. These strategic benefits often justify small quantity sourcing even when short-term financial returns may be lower than mass production alternatives.

Future Evolution and Industry Transformation

The continued development of small quantity sourcing capabilities is reshaping the fashion industry structure, competitive dynamics, and operational models in ways that will have lasting impact on how fashion companies operate and compete.

Manufacturing innovation driven by small quantity sourcing requirements is accelerating the development of flexible, automated, and digitally integrated production systems that will benefit the entire fashion industry. These technological advances are reducing the cost disadvantages of small quantity production while improving quality and sustainability.

Brand differentiation strategies increasingly rely on small quantity sourcing capabilities as mass production becomes commoditized and consumers seek more unique and personalized products. This trend favors companies that can develop sophisticated small quantity sourcing operations while potentially disadvantaging traditional mass producers.

Supply chain evolution toward more flexible, responsive, and collaborative models is being driven partly by small quantity sourcing requirements that demand closer coordination between brands and manufacturers. This evolution is creating new opportunities for specialized suppliers while changing competitive dynamics throughout the supply chain.

Consumer behavior trends toward sustainability, exclusivity, and personalization continue to favor small quantity sourcing approaches over traditional mass production models. These behavioral changes suggest that small quantity sourcing will become increasingly important for fashion companies seeking to remain relevant and competitive.

The transformation enabled by small quantity sourcing in fashion represents more than an operational adjustment—it embodies a fundamental reimagining of how fashion companies can create value through enhanced agility, reduced risk, and stronger sustainability performance. As capsule collections continue to demonstrate the market potential of this approach, small quantity sourcing is establishing itself as an essential capability for fashion companies that seek to thrive in an increasingly complex and demanding marketplace.