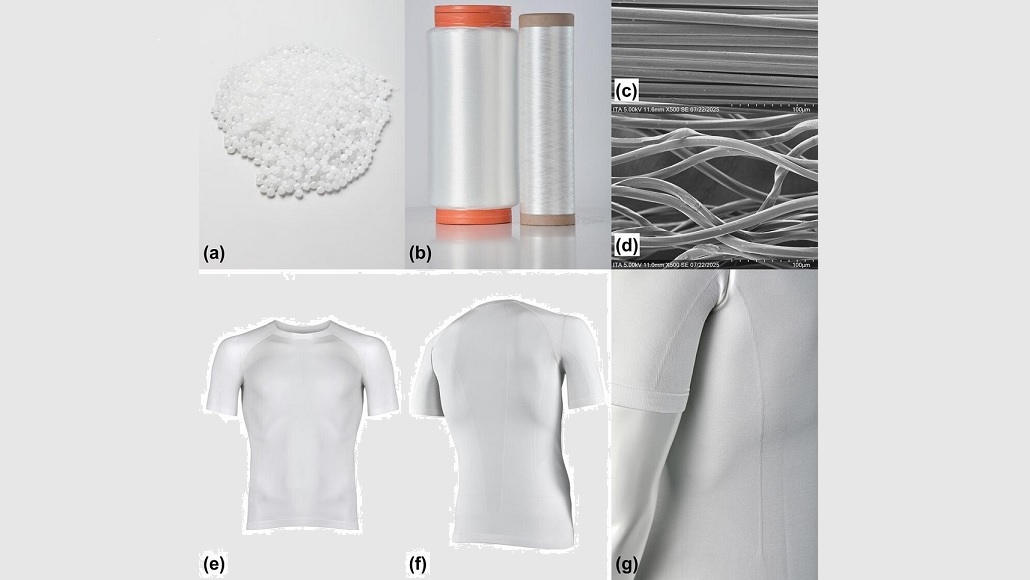

In a significant shift towards sustainability, traditional sports textiles made from petroleum-based synthetic fibers are expected to be replaced by innovative bio-based textiles. Polyethylene, which has primarily been used in the packaging industry, is now being repurposed for textile applications, offering a cost-effective and eco-friendly solution for the future.

The bioPEtex project, part of the BIOTEXFUTURE Innovation Space, involves collaboration among TECNARO from Ilsfeld, BB Engineering from Remscheid, FALKE from Schmallenberg, and the Institut für Textiltechnik (ITA) at RWTH Aachen University. Together, they are pioneering the development of textiles made from bio-based polyethylene (bioPE).

TECNARO is responsible for creating the bio-based polyethylene compounds and overseeing the dyeing process. At the same time, ITA focuses on developing the melt spinning technique for partially oriented yarn (POY) and the false-twisting process for draw-textured yarn (DTY) using the bioPE yarns. BB Engineering will implement the false-twist texturing at an industrial scale, while FALKE is tasked with producing the final T-shirt, which will be finished with a bio-based treatment to enhance its elasticity.

The successful creation of the initial T-shirt using the yarns developed in this project demonstrates the promising qualities of bio-based textiles. This milestone not only showcases the potential for future applications but also sets the stage for evaluating market readiness in subsequent phases. The white BioPE T-shirt is particularly noted for its pleasantly cool and soft texture. However, additional development, characterization, and optimization are required to facilitate its introduction to the market.