The Convergence of Digital Intelligence and Physical Fiber

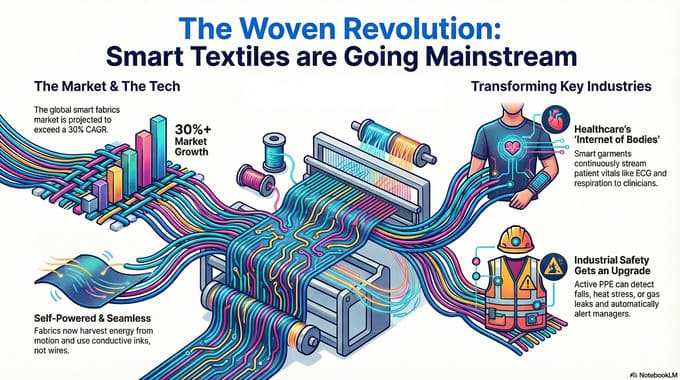

The distinction between the clothes we wear and the computers we carry is rapidly dissolving. For centuries, textiles have served a singular, passive purpose: protection and aesthetic expression. Today, we stand at the precipice of a material revolution where fabrics are transitioning from passive coverings to active, intelligent data interfaces. Smart textile integration represents the next frontier in the Internet of Things (IoT), effectively turning the human body’s surface area into a continuous stream of actionable data.

This shift is not merely an incremental update to “wearable technology” as we know it—clunky wristbands or clipped-on trackers. It is the seamless weaving of conductive polymers, micro-sensors, and energy-harvesting filaments directly into the yarn itself. For commercial leaders, product developers, and investors, this evolution signals a departure from hardware-centric wearables to “disappearing” technology, where the utility remains but the device itself vanishes into the very fabric of everyday life.

The Commercial Renaissance: Market Dynamics and Growth Vectors

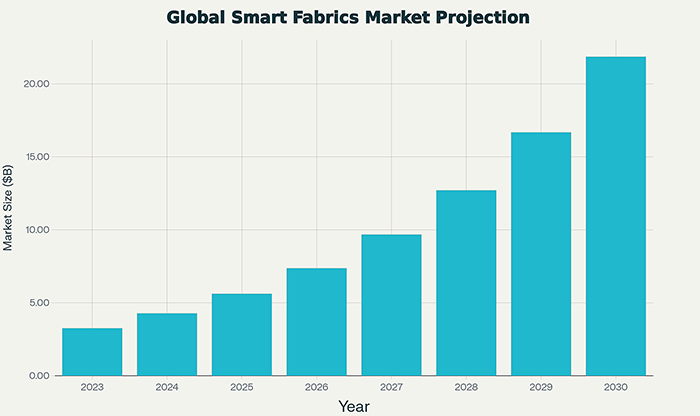

The commercial potential of connected fabrics has moved beyond niche experimentation in aerospace and high-performance athletics. We are witnessing a maturation phase where scalability is becoming viable. Market analysis indicates that the global smart fabrics sector is poised for an aggressive expansion, driven by the miniaturization of electronics and breakthroughs in conductive yarn manufacturing.

The trajectory suggests a compound annual growth rate (CAGR) exceeding 30% over the next decade. This explosive growth is fueled by a “pull” demand from three critical sectors: healthcare, industrial safety, and automotive interiors. Unlike the first generation of e-textiles, which focused on novelty (such as light-up fashion), the current wave of smart textile integration is rooted in solving fundamental commercial and biological problems.

Healthcare: The Internet of Bodies

The most immediate and financially significant application lies in the medical sector. The concept of “remote patient monitoring” is being redefined by sensor textiles. Current innovations allow for the knitting of electrocardiogram (ECG) sensors, electromyography (EMG) monitors, and respiration sensors directly into a patient’s garment.

For the geriatric population or patients recovering from cardiac surgery, this technology removes the friction of traditional medical adherence. There are no patches to stick, no batteries to charge daily, and no heavy boxes to wear. A smart undershirt can continuously stream vitals to a clinician’s dashboard, using AI to detect anomalies before they become emergencies. This capability reduces hospital readmission rates—a key commercial KPI for healthcare providers—and enhances the quality of life for patients. We are moving toward a future where clothing acts as a peripheral nervous system, providing a constant, invisible diagnostic layer.

Industrial and Defense: Enhancing Human Capital Safety

In the industrial sector, smart textile integration is transforming personal protective equipment (PPE) into active safety systems. For mining, oil and gas, and construction enterprises, the cost of workplace injury is astronomical, both in financial terms and human capital.

Next-generation workwear incorporates gas detection sensors, proximity alerts for heavy machinery, and fatigue monitoring systems woven into vests and helmets. In high-risk environments, a smart jacket can detect if a worker has fallen (via accelerometers) or if they are experiencing heat stress (via thermal regulation sensors), automatically triggering an alert to the site manager. In the defense sector, this utility is further heightened. Uniforms are being developed that can detect gunshot wounds, monitor the soldier’s hydration levels, and even transmit secure geolocation data without the need for external radio equipment.

Technological Enablers: The New Material Stack

The commercial viability of these applications rests on specific technological breakthroughs that have occurred in the last 24 months. The barrier to entry has historically been the “hard-soft” interface—the difficulty of connecting rigid electronic components to soft, pliable fabrics.

Conductive Polymers and Graphene Inks

The industry is moving away from weaving metallic wires, which are prone to breakage and discomfort, toward intrinsically conductive polymers and graphene-enhanced inks. These materials allow circuits to be printed or dyed directly onto the fabric. This innovation maintains the hand-feel (drape and softness) of traditional cotton or polyester while enabling full electrical conductivity.

Energy Harvesting: The Power Paradox

Perhaps the most critical development is in energy autonomy. For smart textile integration to succeed commercially, the “charging problem” must be solved. Users will not plug their shirts into a wall outlet. Recent strides in piezoelectric and triboelectric nanogenerators enable fabrics to harvest energy from the wearer’s natural motion and body heat. This breakthrough allows for self-powered sensors that operate indefinitely without external batteries, removing one of the largest hurdles to mass adoption.

Overcoming Barriers to Scale

Despite the optimism, significant challenges remain before connected fabrics become as ubiquitous as denim. The primary commercial bottleneck is no longer science, but manufacturing scalability and durability.

The Washability Standard

For a product to survive in the consumer market, it must survive the washing machine. Smart textile integration requires encapsulation technologies that protect microscopic electronics from water, detergents, and the extreme mechanical agitation of a spin cycle. While standards are improving, achieving a lifespan of 100+ wash cycles without signal degradation remains a primary R&D focus for chemical giants like DuPont and tech firms alike.

Manufacturing Integration

The textile supply chain is centuries old and optimized for speed and low cost, not electronic precision. Commercial success requires a retrofit of the global supply chain. We are seeing the emergence of “digital knitting” machines that can toggle between standard yarn and conductive filament programmatically. This allows for mass customization where the sensor architecture is knitted into the garment during the primary production phase, rather than being stitched on as an afterthought.

The Future Outlook

The era of smart textile integration is unlocking new commercial possibilities that extend far beyond the novelty of early wearable tech. We are entering a phase of “ambient computing,” where the technology surrounding us becomes invisible, intuitive, and omnipresent.

For businesses, the roadmap involves partnering with material scientists and rethinking the data strategy. The data generated by a smart car seat or a connected hospital gown is as valuable as the product itself. As these fabrics become standard, the companies that will capture the most value are not just those that weave the threads, but those that can successfully analyze and monetize the immense tapestry of data they create. The fabric of the future is not just woven; it is coded, connected, and commercially transformative.