ACIMIT, the Association of Italian Textile Machinery Manufacturers, has launched The Heritage, a virtual exhibition that traces the history of Italy’s textile machinery sector. This initiative, developed in partnership with the Italian Trade Agency and financially backed by the Italian Ministry of Foreign Affairs and International Cooperation, showcases over a century of industrial evolution through a digital platform.

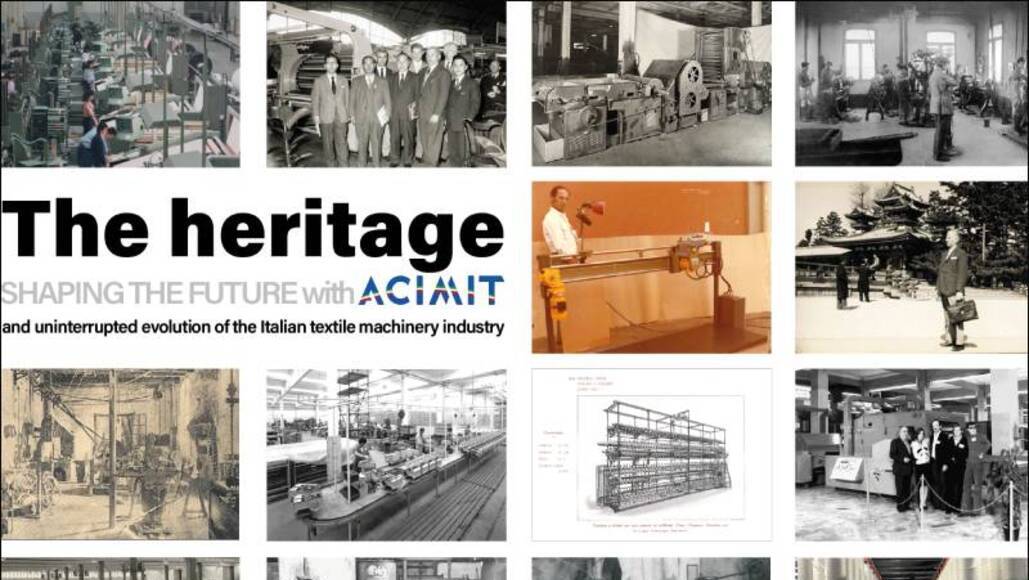

The Heritage acts as a digital extension of the exhibition first presented at ITMA 2023 in Milan, the leading global trade fair for textile machinery. Initially a captivating photographic display for both national and international visitors, this online platform transforms the historical narrative into an immersive and interactive experience.

Featuring contributions from numerous textile machinery companies, The Heritage highlights over 100 years of industry advancements within a visually engaging gallery. The exhibition is organized into several sections, including Machineries, Entrepreneurs, Factories, World, Companies, Exhibition, and ACIMIT, allowing visitors to explore drawings and photographs of iconic machines, significant moments from trade fairs, and vintage images of production plants that have shaped the industry.

ACIMIT President Marco Salvadè emphasized the initiative’s significance: “The primary aim of The Heritage, both at ITMA 2023 and now as a digital platform, is to showcase the history, values, and technological evolution of the Italian textile machinery industry. It offers an evocative and engaging journey that illustrates how Italian manufacturing has progressed over the past century.”

Italy continues to be a global leader in textile machinery, with nearly 300 companies in the sector, driven by extensive expertise and ongoing innovation. Salvadè noted that The Heritage is not a static exhibition but rather a dynamic and evolving space: “This virtual platform will continue to grow, enriched by ongoing contributions from companies sharing images and testimonies that narrate the continuous story of our industry.”

By providing an accessible and engaging platform, The Heritage ensures that the legacy of Italian textile machinery is celebrated and shared globally.