The textile industry is experiencing a transformative era where new age performance fibers have emerged as the cornerstone of modern apparel innovation. Far beyond the basic functionality of conventional fabrics, today’s engineered fibers represent a convergence of advanced material science, consumer wellness demands, and sustainability imperatives. New age performance fibers are fundamentally reshaping how clothing performs, feels, and lasts, creating a paradigm where comfort, durability, and responsibility coexist seamlessly within individual garments.

The revolution in fiber engineering addresses a central paradox that plagued textile innovation for decades: how to create garments that simultaneously offer exceptional performance characteristics—moisture management, temperature regulation, stretch recovery—while maintaining the breathability and comfort consumers demand. Historical solutions required compromises. Cotton offered comfort but absorbed moisture slowly. Synthetic fibers wicked moisture but often felt plastic-like against skin. New age performance fibers dissolve these tradeoffs entirely, delivering multifunctional garments where advanced moisture-wicking capabilities coexist with natural comfort, where durability extends far beyond traditional fabric lifespans, and where engineered properties maintain their integrity through countless washing cycles.

The Science Behind Moisture-Wicking Advancement

Understanding moisture-wicking fibers requires examining the physics underlying their remarkable performance. Traditional fabrics like cotton rely on fiber absorption, where moisture penetrates the fiber structure itself. This approach works but carries inherent limitations—absorbed moisture adds weight, slows evaporation, and creates the unpleasant sensation of clinging garments. New age performance fibers employ fundamentally different mechanisms based on capillary action, where microscopic channels within fiber structures transport moisture away from skin surfaces through rapid transport pathways.

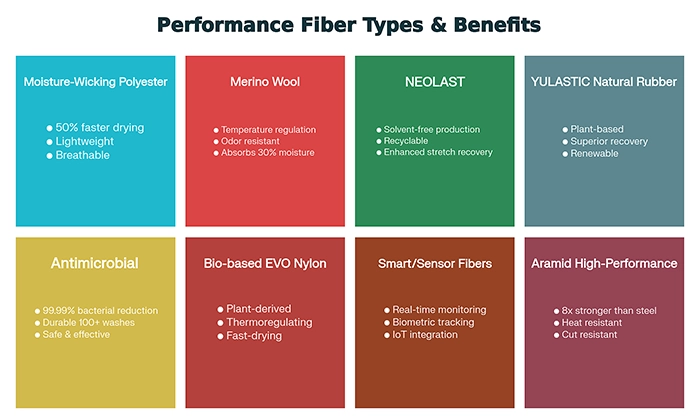

Polyester represents the dominant moisture-wicking material, capable of transporting sweat roughly 50 percent faster than cotton while maintaining significantly lower moisture absorption. The secret lies in polyester’s hydrophobic nature—the fiber actively repels water while its micro-engineered structure creates channels facilitating moisture movement. Modern developments have refined this further through microfiber technology, where individual fibers measure just 1-2 denier—approximately one-hundredth the thickness of human hair. These ultra-fine fibers dramatically increase surface area available for moisture transport, reducing evaporation time to mere minutes rather than hours.

Advanced polyester blends now incorporate engineered cross-sections where fiber geometry itself is optimized for performance. Some formulations employ trilobal structures—fibers with three-sided cross-sections—that increase surface area while maintaining lightweight characteristics. Others integrate hollow-core construction where fibers contain air channels enabling extraordinary moisture capacity alongside rapid drying.

Natural fiber alternatives like Merino wool, traditionally associated with luxury textiles, has emerged as a performance fiber capable of absorbing up to 30 percent of its weight in moisture while maintaining a dry sensation against skin.

Bamboo viscose fibers demonstrate breathability rivaling or exceeding polyester while offering the comfort characteristics of cotton.

Revolutionary Antimicrobial Fabric Technology

The antimicrobial textile revolution emerged from compelling market realities: extended wear periods in performance apparel create environments where odor-causing bacteria flourish, while medical and healthcare sectors face persistent challenges controlling infection vectors through traditional laundering methods. New age performance fibers address these challenges through multiple technological approaches, fundamentally transforming how textiles interact with microbial environments.

Nanocomposite textile technology represents perhaps the most sophisticated antimicrobial approach. Through innovative processes like the Crescoating technique, metal nanoparticles—particularly zinc and silver—are embedded directly within fiber structures rather than merely applied to surfaces. This distinction proves critical to durability and effectiveness. Traditional surface-coated antimicrobial textiles lose efficacy through normal washing as particles gradually leach away. Nanocomposite fibers with embedded nanoparticles demonstrate unprecedented longevity, retaining antimicrobial properties after 100+ washing cycles.

Alternative antimicrobial approaches leverage chemistry rather than nanoparticles. Advanced fibers incorporate copper ions or silver ions distributed throughout fiber matrices, creating sustained antimicrobial environments. Some formulations employ photocatalytic mechanisms where fiber treatments interact with light exposure to generate antimicrobial effects. Others integrate plant-based antimicrobial compounds—essential oils, chitosan extracts, or tea tree derivatives—providing natural antimicrobial properties without synthetic chemical application.

Elastane Alternatives and Stretch Fiber Innovation

The limitations of traditional elastane—petroleum-based dependency, recycling incompatibility, and environmental concerns—created urgent industry demand for revolutionary alternatives. New age performance fibers emerging within the stretch fiber category address these challenges through fundamentally reimagined approaches to elasticity and recovery.

NEOLAST fibers developed through Celanese Corporation represent a paradigm shift in performance stretch fiber production. Unlike traditional elastane employing chemically-intensive wet spinning processes, NEOLAST utilizes proprietary solvent-free melt-extrusion technology eliminating hazardous chemicals historically integral to spandex manufacturing. This manufacturing innovation delivers multiple benefits simultaneously: dramatically reduced environmental impact, enhanced recyclability through thermoplastic elastoester polymers, and superior performance characteristics including extended stretch recovery and durability. Critically, NEOLAST addresses the circular economy challenge where traditional elastane-blended fabrics resist recycling because elastane incompatibility prevents existing recycling infrastructure from processing blended materials effectively.

Natural rubber-based alternatives provide additional innovation pathways. YULASTIC represents a plant-based stretch fiber derived from natural latex harvested from rubber tree plantations. Plant-derived elasticity offers intrinsic advantages including superior elastic recovery compared to petroleum-based alternatives, genuine renewability through sustainable plantation management, and biodegradability at end-of-life. Laboratory performance testing demonstrates that YULASTIC matches or exceeds synthetic elastane across critical metrics including strength, elongation, and durability while delivering that crucial advantage: garments maintain their shape longer with minimal sagging through extended wear cycles.

Bio-based elastane alternatives represent another innovation frontier. Recent developments employ plant-derived polymers, with formulations incorporating renewable resources including corn-based feedstock. One notable example combines bio-based elastane incorporating 98 percent renewable materials with bio-nylon fibers derived from castor beans and industrial corn. Testing reveals that these bio-based blends deliver 27 percent lower carbon footprints and 82 percent reduced ozone depletion potential compared to conventional spandex while maintaining elasticity and durability expectations established by traditional stretch fibers.

Smart Textiles and Embedded Intelligence

Perhaps the most visionary category within new age performance fibers comprises smart textiles where embedded sensors and responsive technologies transform garments into intelligent wearable systems. These textiles represent the frontier of fiber engineering where material science intersects with electronics and artificial intelligence.

Smart fiber technology encompasses multiple technical approaches. Conductive fibers integrated into fabric structures create touch-responsive surfaces where garments function as flexible computer interfaces. Integrated sensors can monitor physiological metrics including heart rate, muscle activity, respiration, and hydration status, transmitting real-time data to connected devices. Temperature-responsive fibers adjust thermal properties dynamically responding to environmental conditions—increasing insulation in cold environments while enhancing breathability during heat exposure.

Leading technology examples demonstrate practical implementation. Google’s Jacquard technology weaves conductive fibers into fabrics creating haptic sensing textiles enabling remote device control through gesture recognition. The textile essentially becomes a wearable interface where specific touch gestures trigger predetermined actions. MIT’s OmniFiber project developed stretchable sensors embedded directly into fibers enabling unprecedented integration of sensing capability without compromising comfort or aesthetic appeal. These embedded fiber sensors can detect pressure, strain, and temperature changes, converting mechanical stimuli into electrical signals processed by integrated microcontrollers.

Medical and rehabilitation applications drive significant smart textile innovation. Compression garments incorporating position sensors and temperature monitors track recovery progress while alerting patients and healthcare providers to complications. Performance apparel with embedded EMG (electromyography) sensors monitors muscle activation patterns, helping athletes optimize training techniques and preventing injury through real-time form analysis. Infection prevention textiles incorporating antimicrobial properties alongside temperature and humidity monitoring represent hospital environments where smart performance textiles simultaneously protect patients while providing diagnostic information.

Durability Revolution Through Advanced Fiber Engineering

Modern consumers increasingly recognize that apparel durability represents an overlooked sustainability metric. Garments extending functional life through superior durability substantially reduce the environmental burden compared to frequently replaced cheaper alternatives requiring more frequent manufacturing, transportation, and disposal cycles. New age performance fibers integrate advanced durability characteristics through multiple engineering approaches.

Four-way stretch fabric technology exemplifies durability innovation. While traditional stretch fabrics offer elasticity in a single direction or limited directions, engineered performance fibers enable multidirectional stretch combined with sustained recovery across thousands of extension cycles. This characteristic proves essential for demanding athletic applications where complex body movements require simultaneous multidirectional stretch.

Nanofiber integration enhances durability through multiple mechanisms. Nano-enhanced fibers exhibit increased tensile strength and abrasion resistance compared to conventional fiber alternatives. The embedding of nanoparticles within fiber structures fundamentally alters material properties at molecular scales, creating denser fiber matrices resistant to mechanical wear. Research demonstrates that nanocomposite textiles withstand abrasion testing demonstrating significantly extended wear durability, translating directly into garments maintaining appearance and performance through extended service periods.

Chemical resilience represents another durability dimension. Advanced performance fibers exhibit enhanced resistance to degradation from exposure to cleaning agents, UV radiation, sweat chemistry, and environmental pollutants. This chemical resilience proves essential for industrial applications, outdoor gear enduring harsh environmental exposure, and medical textiles requiring sterilization through aggressive chemical protocols.

Application Expansion Across Industry Sectors

The sophistication of new age performance fibers has catalyzed expansion far beyond traditional athletic wear into diverse application domains. This expansion trajectory reflects recognition that enhanced performance characteristics deliver genuine value across substantially broader consumer and industrial applications than traditional fiber marketing suggested.

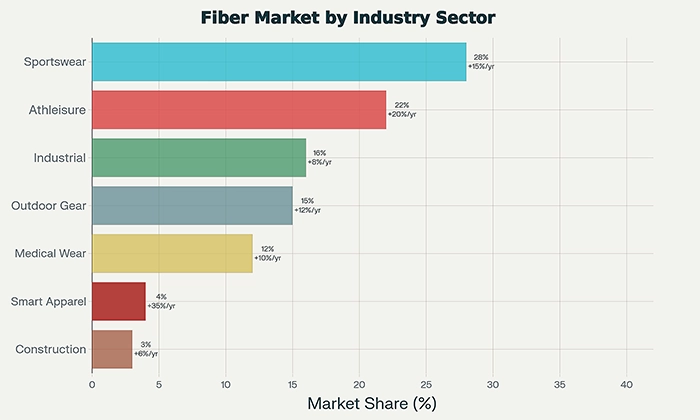

Sportswear remains the flagship application domain, with new age performance fibers enabling unprecedented apparel capabilities. Running and training applications benefit from moisture-wicking properties maintaining dry sensations during extended exertion, antimicrobial treatments eliminating odor concerns enabling extended wear, and flexibility engineering facilitating complete freedom of movement. Professional athletes now routinely specify performance fiber characteristics meeting sport-specific demands, creating demand cascading through enthusiast and recreational markets.

Athleisure represents perhaps the highest-growth application segment where performance fiber characteristics enable comfortable everyday wear retaining aesthetic appeal alongside functional sophistication. Performance textiles incorporated into casual clothing, office environments, and social settings reflect cultural shifts toward active lifestyles and comfort prioritization. Market data indicates that athleisure applications demonstrate 20 percent annual growth rates, substantially outpacing traditional sportswear growth trajectories.

Outdoor and adventure applications drive particular demand for performance fiber innovations. Multi-day hiking, mountaineering, and expedition activities where garment failure carries serious consequences demand extraordinary durability and functional sophistication. Moisture management becomes critical in variable temperature environments where rapid transitions between exertion and rest create evaporative cooling risks. UV protection through fiber engineering prevents sun damage during extended exposure at high altitudes or in reflective environments. Water resistance maintained across extended exposure and mechanical stress represents essential functionality for expedition textiles.

Medical and healthcare applications represent particularly sophisticated performance fiber utilization. Compression garments incorporate graduated elasticity engineered through advanced fiber technologies enabling therapeutic benefits while maintaining comfort during extended wear. Antimicrobial fibers address infection prevention in clinical environments while supporting hygiene in rehabilitation settings where patients require extended garment contact. Temperature-regulating fibers assist in managing patient comfort during recovery periods. Hospital gowns and medical apparel increasingly incorporate performance fiber characteristics transforming them from utilitarian necessity into functional garments enhancing patient dignity and therapeutic outcomes.

Market Expansion and Industry Growth Trajectory

The global performance fabric market reflects substantial expansion driven by new age performance fiber innovation. Current market valuation approaches 80 billion annually with projections indicating growth to 114.66 billion by 2033, representing a compound annual growth rate of 3.9 to 4.1 percent. This steady expansion reflects consistent innovation deployment across established applications alongside continuous expansion into new domains.

Material segmentation within the performance fiber market reveals polyester dominance capturing 35.5 percent market share, followed by nylon at 22.3 percent, spandex at 18.7 percent, aramid fibers at 12.5 percent, and emerging alternatives at 10 percent. This distribution reflects polyester’s cost-effectiveness, versatility, and proven performance characteristics alongside emerging pressure from sustainable alternatives and specialized materials addressing specific functional requirements.

Regional market dynamics demonstrate particular growth momentum in Asia-Pacific regions where established textile manufacturing infrastructure combines with rising consumer demand for premium performance apparel. India’s performance fiber market demonstrates exceptional growth trajectory driven by “Make in India” initiatives, cost advantages, and expanding domestic consumer demand. Simultaneously, North American and European markets emphasize innovation in smart textiles, sustainable alternatives, and healthcare applications reflecting regulatory pressures and consumer sophistication valuing advanced functionality.

Integration of Flexibility and Comfort Engineering

Contemporary new age performance fibers prioritize comfort as explicitly as durability and functionality, reflecting recognition that performance apparel only achieves market adoption when comfort expectations are met.

Fiber finesse—measuring fiber diameter—represents a critical comfort parameter where new age performance fibers deliver substantial improvements. Microfibers and nanofibers create textiles with substantially softer hand-feel compared to conventional fibers of equivalent functional characteristics. The ultra-fine structure increases fabric surface smoothness while reducing the scratchy sensations historically associated with synthetic performance apparel.

Stretch recovery represents another comfort dimension where new age performance fibers excel. Garments incorporating advanced elastane alternatives and engineered stretch fibers maintain their fit and shape through extended wear periods. This comfort benefit extends beyond appearance—properly fitted garments reduce chafing, improve freedom of movement, and prevent the bunching or sagging that creates discomfort. Medical compression garments incorporating advanced stretch fiber engineering maintain therapeutic compression throughout wear periods without requiring frequent adjustment or causing circulation concerns from garment slippage.

Sustainability Considerations in Advanced Fiber Development

The emergence of new age performance fibers reflects broader industry recognition that contemporary textile innovation must simultaneously address performance and environmental imperatives. Advanced fiber development increasingly prioritizes sustainability through multiple mechanisms from renewable material sourcing through advanced manufacturing techniques reducing environmental burden.

Bio-based fiber development represents a primary sustainability approach where new age performance fibers incorporate increasing percentages of renewable material inputs. Plant-derived polymers sourced from sustainable agricultural systems reduce dependency on petroleum-based synthetics. Bio-based elastane alternatives eliminate fossil fuel reliance in stretch fiber production while enabling genuine end-of-life biodegradability. Advanced nylon fibers derived from castor oil and corn address performance requirements while incorporating renewable feedstocks.

Manufacturing process innovation offers parallel sustainability benefits. Solvent-free production techniques eliminate hazardous chemical utilization and waste streams characterizing traditional fiber manufacturing. Water-conserving dyeing and finishing technologies substantially reduce consumption of this precious resource. Energy-efficient production methods lower carbon footprints associated with fiber creation. These manufacturing innovations often deliver economic benefits alongside environmental improvements, creating market incentives aligning business performance with sustainability objectives.

Recycling compatibility represents a critical sustainability consideration increasingly addressed through new age performance fiber development. Traditional elastane-containing garments resist recycling because elastane incompatibility prevents existing infrastructure from processing blended materials effectively. Novel elastane alternatives demonstrate compatibility with established recycling systems or enable development of specialized recycling infrastructure.

Looking Toward Future Performance Fiber Evolution

The trajectory of new age performance fiber development suggests continued acceleration across multiple dimensions. Emerging innovations currently in early commercialization stages will mainstream within five to ten years, fundamentally shifting performance baseline expectations. Graphene-enhanced fibers promise dramatically increased strength, enhanced thermal properties, and novel functionalities currently unavailable through conventional fiber engineering. Programmable smart textiles incorporating advanced phase-change materials will enable dynamic temperature regulation responding precisely to microenvironment conditions. Regenerative medical textiles will transition from experimental concepts toward clinical deployment, providing therapeutic benefits simultaneously with protective functionality.

The evolution toward new age performance fibers represents not merely technological advancement but fundamental redefinition of what textiles accomplish within modern life. This transformation positions new age performance fibers as essential infrastructure underlying athletic achievement, medical rehabilitation, occupational safety, and everyday comfort aspirations across global populations. The convergence of advanced material science, consumer demand, and sustainability imperatives ensures that performance fiber innovation will remain central to textile industry evolution for decades to come.