Understanding Premium Fabric Innovation in Modern Apparel

Premium fabric innovation represents a fundamental shift in how contemporary manufacturers approach textile engineering. Rather than focusing solely on aesthetic appeal, producers are integrating advanced material science, nanotechnology, and engineered fiber systems to create apparel that performs beyond conventional expectations. The convergence of consumer demand for functionality, durability, and environmental responsibility has catalyzed a market transformation where premium fabric innovation stands as a primary value differentiator.

The global premium apparel market reached USD 384.84 billion in 2025, reflecting robust consumer appetite for higher-quality products. This expanding market directly correlates with increased interest in premium fabric innovation, as discerning consumers recognize that superior materials directly influence garment longevity, comfort, and performance. The premium apparel segment now growing at a 7.5% CAGR through 2035, demonstrating sustained momentum in consumer preference for elevated quality and innovative textile solutions.

The Evolution of Engineered Materials in High-Value Apparel

Engineered materials represent the cornerstone of premium fabric innovation. The global engineered fabrics market, valued at USD 32.54 billion in 2024, is projected to reach USD 44.36 billion by 2030, growing at a 5.3% CAGR. These technologically advanced materials transcend traditional fiber categories, incorporating synthetic innovations, bio-based alternatives, and hybrid compositions that deliver specific performance characteristics tailored to distinct applications.

The sophistication underlying engineered materials stems from precision manufacturing and material science advancement. Polyester, enhanced through advanced processing techniques, has emerged as a leading material in the premium segment due to its exceptional versatility and adaptability. Modern polyester innovations include wrinkle resistance, moisture-wicking capabilities, and durability enhancements that justify premium positioning. Simultaneously, luxury fiber blends combining natural materials with engineered components are capturing significant market share among consumers seeking the tactile luxury of natural fibers enhanced by technological performance benefits.

The application of premium fabric innovation extends across diverse market segments. Fashion and casual wear captured 65.71% of luxury apparel revenue in 2024, while emerging athleisure categories are expanding at a 5.21% CAGR. This diversification demonstrates how premium fabric innovation serves multifaceted consumer needs, from everyday comfort wear to high-performance athletic applications and professional corporate textiles.

Nanotechnology and Smart Textile Innovations

Nanotechnology represents one of the most transformative technologies driving premium fabric innovation. Market research indicates that over 35% of consumers now actively seek nanotechnology-enhanced features in premium apparel, reflecting widespread recognition of performance benefits. Nanostructured materials enable the development of fabrics with unprecedented properties including self-cleaning surfaces, antimicrobial protection, moisture-wicking efficiency, and stain resistance.

The sophistication of nanotechnology applications within textiles encompasses multiple technological pathways. Nanofiber webs, constructed from ultra-fine fibers produced through electrospinning, create highly porous structures offering exceptional strength-to-weight ratios. These innovative fabric architectures deliver lightweight performance without compromising durability, making them ideal for both luxury sportswear and premium workwear applications. Currently, over 30% of high-performance apparel incorporates such smart material traits, marking a significant industry shift toward technology-enabled textiles.

Composite fibers based on nanostructures embed nanomaterials into fiber matrices, enhancing mechanical, electrical, and thermal properties. These advanced developments enable smart textiles that can monitor health metrics, adjust to environmental conditions, and provide interactive functionality. The integration of conductive nanomaterials allows for touch-responsive fabrics and power-harvesting textiles, positioning premium fabric innovation at the convergence of fashion and wearable technology. More than 45% of new textile technology investments are now directed toward nanotechnology development, highlighting the sector’s strategic prioritization of these advanced materials.

Luxury Fabrics and Raw Material Leadership

The luxury fabric segment, valued at USD 4.45 billion in 2024 and projected to reach USD 8.32 billion by 2030, demonstrates exceptional growth potential driven by premiumization trends. Within this market, silk maintains dominant positioning with a 24.5% market share, prized for its natural sheen, unmatched texture, and timeless association with luxury. Velvet continues gaining traction among contemporary consumers, reappearing in premium collections due to its rich texture and opulent aesthetic appeal. Cashmere and fine cotton blends serve the luxury segment’s dual demand for tactile comfort and exclusivity, while innovative jacquard weaving creates intricate patterns appealing to discerning consumers seeking detailed expression through fabric design.

Premium fabric innovation within luxury categories transcends fiber selection, encompassing advanced finishing techniques and technological enhancements. Luxury manufacturers are integrating stain resistance coatings, anti-crease treatments, and smart textile finishes that preserve the aesthetic and tactile qualities of luxury materials while elevating functional performance. This hybrid approach allows consumers to enjoy the sensory pleasure of premium natural fibers enhanced by modern performance characteristics, fundamentally changing value perceptions within luxury apparel markets.

The integration of sustainable luxury fabrics represents a significant evolution in premium fabric innovation. Bio-based fibers including Tencel, Seacell, and those derived from algae or mushroom mycelium exemplify how innovation can reduce reliance on resource-intensive conventional materials. The global recycled textile market is forecast to grow at a 3.6% CAGR during 2025-2033, indicating substantial consumer demand for sustainable premium options. Luxury brands increasingly incorporate post-consumer recycled textiles and organic materials, demonstrating that premium fabric innovation encompasses environmental stewardship alongside performance enhancement.

Consumer Preferences Driving Market Expansion

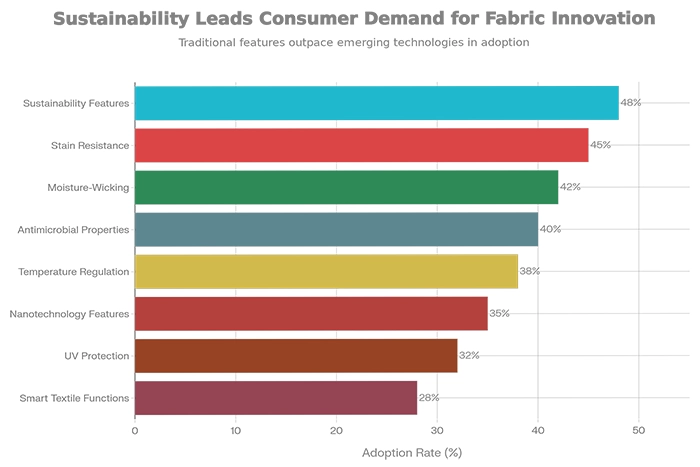

Consumer preferences for premium fabric innovation reveal distinct prioritization patterns across performance characteristics. Sustainability features lead adoption rates at 48%, reflecting conscious consumer values. Stain resistance follows at 45%, addressing practical durability concerns. Moisture-wicking properties appeal to 42% of premium apparel consumers, particularly within athleisure and performance-focused segments. Antimicrobial properties attract 40% of consumers, with heightened health consciousness driving demand for hygienic textile solutions. Temperature regulation capabilities appeal to 38% of purchasers, while nanotechnology features attract 35% seeking cutting-edge innovation. UV protection registers 32% adoption interest, and smart textile functions appeal to 28% of consumers exploring interactive, technology-integrated apparel.

This consumer preference hierarchy directly influences product development strategies and market positioning. Brands investing in premium fabric innovation increasingly prioritize sustainability alongside performance, recognizing that contemporary luxury consumers demand both ethical production and superior functionality. Corporate apparel and promotional textile segments are particularly responsive to these consumer preference shifts, with decision-makers increasingly specifying premium fabric innovations to enhance brand perception and employee satisfaction. The functional apparel market, reaching USD 611.34 billion by 2030 and expanding at 6.3% CAGR, demonstrates how performance-driven fabric innovations are reshaping entire market segments.

Advanced Manufacturing Technologies Enabling Premium Fabric Innovation

Premium fabric innovation depends critically on manufacturing sophistication. Digital printing technology, AI-driven pattern generation, and automated cutting systems have revolutionized production capabilities, enabling faster prototyping and more precise quality control. These technologies compress design-to-market timelines from weeks to days, allowing brands to respond rapidly to consumer preference shifts while minimizing inventory risk. Nanotechnology applications incorporating graphene and other advanced nanomaterials create lighter, stronger, and more conductive fabrics, expanding the performance envelope achievable through premium fabric innovation.

The automation of manufacturing processes, including robotics and semi-autonomous production lines, is returning textile production to developed economies where labor costs previously precluded competitive manufacturing. This geographic recalibration enables European, North American, and Japanese manufacturers to focus on innovation and quality control, establishing their competitive advantage through technological sophistication rather than cost reduction. Simultaneously, manufacturing facilities in Vietnam, Indonesia, and India are upgrading infrastructure to maintain export competitiveness through adoption of these advanced technologies.

Three-dimensional weaving and knitting technologies represent emergent manufacturing innovations enabling previously impossible fabric architectures. These additive manufacturing approaches allow for complex structural designs, integrated functionality, and customized fiber arrangements optimized for specific performance requirements. The convergence of digital design tools with advanced fabrication technologies is democratizing access to innovative textiles, allowing smaller specialty manufacturers to develop proprietary premium fabric innovations that differentiate their market positioning.

Industry Applications and Market Segmentation

Premium fabric innovation demonstrates particular importance across specialized applications. Corporate and professional apparel segments increasingly specify premium fabrics for executive uniforms, workwear, and branded merchandise, recognizing that material quality directly communicates organizational values and professionalism. Luxury hospitality and retail environments incorporate high-end fabrics for furnishings, uniforms, and guest-facing materials, with premium fabric innovations enhancing experiential design while improving durability and maintainability.

The automotive industry emerges as a significant adopter of premium fabric innovation, utilizing advanced textiles for interior components, seating surfaces, and acoustic applications. Luxury vehicle manufacturers prioritize engineered materials offering aesthetic refinement combined with superior durability, stain resistance, and temperature regulation. Private aviation and yacht interiors represent ultra-premium segments where fabric innovations command exceptional pricing, supporting substantial R&D investments in proprietary material developments.

Promotional and branded merchandise applications benefit substantially from premium fabric innovation. Organizations leveraging customized, high-quality apparel for employee uniforms, promotional distributions, and brand activation campaigns increasingly recognize that superior fabric construction enhances brand perception while improving product longevity and consumer satisfaction. This market segment is experiencing accelerated growth as companies recognize that investment in premium fabric innovation delivers measurable returns through enhanced brand differentiation and improved customer engagement.

The Role of Technology Integration in Fabric Performance

Smart textiles incorporating embedded sensors, conductive yarns, and responsive coatings represent the frontier of premium fabric innovation. Health-monitoring fabrics capable of tracking vital signs in real-time are transitioning from research applications to commercial availability, expanding market opportunities beyond traditional apparel. Temperature-responsive fibers adjust insulation properties based on environmental conditions, delivering adaptive comfort without garment changes. Photochromic and thermochromic dyes enable color-changing fabrics that provide interactive aesthetic experiences, appealing to fashion-forward consumers and innovative brand expressions.

IoT integration enables smart fabrics to connect with digital ecosystems, collecting and transmitting performance data. This connectivity transforms apparel into information-gathering systems, providing wearers with real-time feedback on activity, hydration, and health metrics. For organizations utilizing branded apparel for employee wellness programs or athletic teams, these advanced capabilities create differentiated value propositions justifying premium pricing and demonstrating organizational commitment to employee wellbeing.

The development of self-cleaning and self-healing fabric technologies exemplifies how premium fabric innovation extends product lifecycles while reducing waste. Nanoparticle coatings enable fabrics to resist bacterial growth and repel stains, reducing cleaning frequency and extending garment usability. Self-healing fibers capable of repairing minor tears or damage preserve garment functionality, directly addressing sustainability imperatives by reducing disposal rates and extending useful garment life. These innovations align premium fabric innovation with circular economy principles, creating products that simultaneously deliver superior performance and environmental benefits.

Market Dynamics and Competitive Positioning

The luxury fabric market’s expansion at 11% CAGR significantly exceeds general apparel market growth rates, indicating robust premium positioning and strong pricing power. This differential growth reflects consumer recognition that premium fabric innovation delivers tangible value through improved comfort, longevity, and performance. Brands successfully commercializing premium fabric innovations command pricing premiums that more than offset elevated material costs, creating attractive profit opportunities that incentivize continued R&D investment.

Partnerships between fashion houses, technology companies, and material science innovators are accelerating premium fabric innovation commercialization. These collaborative ecosystems enable rapid knowledge transfer, reducing development timelines and facilitating faster market entry for innovative solutions. Established luxury brands are particularly active in forming strategic technology partnerships, recognizing that maintaining market leadership requires continuous innovation in fabric capabilities and performance characteristics.

Brand differentiation increasingly depends on proprietary fabric innovations that competitors cannot immediately replicate. Companies investing in distinctive textile technologies establish competitive moats protecting market position and justifying premium pricing. The development of unique fiber blends, exclusive finishing techniques, and specialized manufacturing processes creates competitive advantages that translate to sustained revenue premiums. Marketing communications emphasizing distinctive fabric innovations have become essential components of luxury brand positioning strategies, with companies highlighting nanotechnology applications, smart textile integrations, and sustainable material sourcing as key value propositions.

Sustainability and Environmental Considerations

Environmental consciousness has become integral to premium fabric innovation development. Advanced manufacturing techniques including waterless dyeing systems, reduced chemical processing, and efficient fiber production decrease environmental footprint while maintaining superior performance. These sustainability-focused innovations address regulatory pressures and consumer expectations simultaneously, positioning environmentally responsible premium fabrics as both ethical choices and technically superior solutions.

The integration of biodegradable sensors into smart textiles, solar-powered textile applications, and compostable fiber alternatives represents the convergence of sustainability and technological innovation. These developments allow premium fabric innovations to serve environmental objectives while maintaining or enhancing performance capabilities. Luxury brands increasingly market sustainability credentials as premium positioning elements, recognizing that contemporary affluent consumers equate environmental stewardship with quality and sophistication.

Certification systems including organic fiber verification, recycled content documentation, and sustainability standard compliance are becoming essential components of premium fabric marketing. Third-party certifications enhance consumer trust and facilitate price premiums, supporting the commercial viability of sustainability-focused premium fabric innovations. Organizations implementing transparent supply chain practices and demonstrating genuine environmental commitment are capturing growing market segments prioritizing ethical luxury.

Market Outlook and Future Trajectory

The premium fabric innovation market demonstrates compelling growth prospects through 2030 and beyond. The luxury fabric market CAGR of 11%, combined with functional apparel expansion at 6.3% CAGR and engineered fabric growth at 5.3% CAGR, indicates sustained market expansion across multiple segments. Emerging technologies including AI-powered design tools, advanced biotechnology applications, and nanotechnology breakthroughs are positioning the sector for continued innovation acceleration.

Consumer demand for premium fabric innovation shows no signs of abating, with ongoing premiumization trends across global markets and particularly robust growth in Asian emerging markets where rising middle-class populations are embracing luxury consumption. The shift toward sustainable premium options, integration of smart technologies, and emphasis on personalization are creating expanded market opportunities beyond traditional luxury segments.

Organizations positioning themselves as leaders in premium fabric innovation are investing substantial capital in R&D capabilities, technology partnerships, and manufacturing infrastructure. The competitive landscape will likely consolidate around companies successfully combining material science expertise with technology integration capabilities and sustainable production methodologies. Companies achieving this integration will capture disproportionate market share and premium pricing, establishing leadership positions in the expanding premium fabric innovation sector.