The textile industry stands at a transformative crossroads as digital textile printing for high precision customization reshapes how manufacturers and designers approach fabric production. Unlike traditional screen printing methods that demand extensive setup times and substantial minimum order quantities, modern digital textile printing technology enables businesses to produce intricate, multi-colored designs with remarkable accuracy while maintaining cost efficiency and sustainability. This revolutionary shift has fundamentally altered the competitive landscape, allowing companies of all sizes to respond rapidly to market trends and consumer demands for personalized apparel and promotional products.

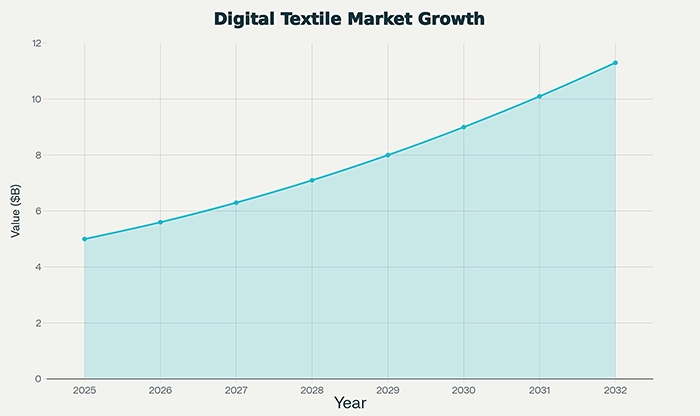

The global digital textile printing market reflects this transformation, having reached a valuation of US5 billion in 2025 and projected to surge to US11.3 billion by 2032, representing a compound annual growth rate of 12.5 percent. This explosive growth underscores the industry’s recognition that digital textile printing technology represents not merely an incremental improvement over conventional methods, but a fundamental reimagining of production capabilities. Manufacturers who embrace this technology gain competitive advantages through accelerated time-to-market, enhanced design flexibility, and substantially reduced operational costs.

Understanding the Technological Foundation

Core Technologies Driving the Revolution

The foundation of modern digital textile printing rests upon sophisticated inkjet technology combined with advanced ink formulations and precision printhead engineering. Digital printers employ specialized water-based pigment inks that penetrate fabric fibers with exceptional accuracy, creating designs that resist fading through multiple wash cycles while maintaining vibrant color saturation. The technology operates through a process where digital design files are converted into precise droplet patterns, with each microscopic ink droplet positioned with extraordinary accuracy to reproduce the intended design with photorealistic fidelity.

Direct-to-Garment (DTG) printing represents one primary category, utilizing inkjet technology to apply water-based inks directly onto fully assembled garments. This approach proves particularly advantageous for small-batch customization and personalized apparel, where individual designs can be printed on demand without requiring screen preparation or setup time. DTG systems can achieve print resolutions reaching 1440 x 1440 dots per inch, enabling reproduction of fine details and smooth color gradients that traditional methods cannot replicate.

Direct-to-Film (DTF) printing comprises the second major technology segment, wherein designs are first printed onto specialized polyester film, then transferred to fabric using heat press equipment. DTF technology has experienced explosive adoption, with an estimated 7 billion items produced using this method in 2024 alone, now accounting for approximately 50 percent of all global T-shirt decorations. The DTF process enables printing on a broader range of fabric compositions, including challenging materials like fleece, nylon, and polyester blends, with exceptional durability and color vibrancy.

DTG vs DTF Technology Comparison:

| Feature | DTG Printing | DTF Printing |

|---|---|---|

| Print Resolution | Up to 1440 x 1440 DPI | High resolution with sharp details |

| Fabric Compatibility | Cotton and cotton-blend garments | Wide range: cotton, polyester, blends, fleece, nylon |

| Production Speed | 5+ minutes per garment | Faster production per unit |

| Color Vibrancy | Photorealistic with gradients | Vibrant, durable prints |

| Best Applications | Small-batch, personalized apparel | High-volume runs, promotional items |

| Durability | Excellent wash fastness | Exceptional durability |

| Setup Requirements | Minimal, on-demand capable | Quick setup, film-based transfer |

Color Accuracy and Visual Excellence

Achieving Superior Color Reproduction

The pursuit of color perfection in digital textile printing for high precision customization requires sophisticated management systems and advanced ink chemistry. Modern digital textile printers utilizing extended color gamut technology—combining traditional cyan, magenta, yellow, and black inks with supplementary orange, green, and violet channels—can accurately reproduce approximately 90 percent of Pantone spot colors. This technical achievement represents a substantial advancement over traditional CMYK systems, which typically reproduce only 60 percent of branded spot colors.

Water-based pigment inks used in contemporary digital systems offer 40 percent environmental improvement compared to conventional screen printing methods, while simultaneously delivering color vibrancy and wash fastness properties that exceed customer expectations. These advanced formulations achieve color saturation through molecular bonding with fabric fibers rather than surface coating, resulting in prints that feel soft to the touch and maintain aesthetic appeal across numerous laundering cycles.

Color management in high precision printing systems demands calibrated spectrophotometers and sophisticated ICC profiling protocols to ensure consistency across diverse fabric substrates and production batches. Modern digital systems incorporate intelligent temperature control mechanisms and automatic printhead protection systems that maintain color accuracy throughout extended production runs, eliminating the color drift and inconsistency characteristic of older technologies.

Precision, Speed, and Scalability

On-Demand Production and Rapid Adaptation

The acceleration of production timelines represents one of digital textile printing technology’s most significant competitive advantages. High-speed single-pass printers now achieve production capacities reaching 1,080 square meters per hour while maintaining photorealistic resolution and color accuracy. These systems eliminate minimum order quantity constraints, enabling economically viable print-on-demand business models for single-unit orders through to large-scale production runs.

Traditional manufacturing approaches require substantial upfront commitments to inventory, with studies indicating that 30 to 40 percent of conventionally manufactured garments ultimately go unsold, generating waste and financial losses. Digital textile printing enables a fundamentally different operational philosophy wherein production precisely matches actual demand. This capability transforms businesses’ ability to maintain financial liquidity, allocate capital strategically, and respond to emerging market trends without carrying excessive dead stock.

The scalability inherent to digital textile printing technology accommodates everything from custom promotional merchandise featuring individual company logos through to complete seasonal fashion collections. Designers can conduct rapid prototyping and iterate designs based on customer feedback without incurring substantial costs or delays. This flexibility proves particularly valuable in fast fashion environments where design cycles have compressed from traditional monthly updates to weekly or even daily modifications.

Enhanced Design Possibilities

Unlimited Creative Expression

Digital textile printing for high precision customization eliminates the design constraints that plague traditional screen printing methods. Conventional approaches typically support only 9 colors before cost escalation becomes prohibitive, whereas digital systems can reproduce up to 16 million color variations without incurring additional setup costs. Designers can incorporate photorealistic gradients, intricate patterns, fine artistic details, and complex multi-layered graphics that would be technically impossible or economically unfeasible using conventional methods.

The technology’s ability to handle complex design elements enables unprecedented possibilities for personalization and customization. Fashion brands leverage this capability to offer exclusive collections featuring limited-edition designs that provide customers with a sense of individuality and uniqueness. Mass customization—the ability to produce personalized items economically at production scale—has transitioned from theoretical concept to practical reality through advances in digital textile printing technology.

Professionals working with high-resolution image files at 300 DPI maintain exceptional print quality even across large fabric surfaces, with acceptable results achievable at 150 DPI for designs intended to be viewed from a distance. This technical specification ensures that photographic-quality prints and intricate artwork reproduce with remarkable fidelity, opening possibilities for textile applications spanning fine art reproduction, museum-quality reproductions, and fashion-forward designs that demand technical precision.

Environmental Responsibility and Sustainability

Ecological Advantages of Modern Textile Printing

The environmental impact of fabric production represents a critical consideration for manufacturers and conscious consumers alike, and digital textile printing technology delivers measurable ecological advantages over traditional methods. Digital systems reduce water consumption by up to 95 percent compared to conventional rotary screen printing, which demands extensive washing and rinsing processes. The precise droplet deposition of inkjet technology eliminates wasteful ink application, with every droplet contributing to the final design rather than being absorbed into unused areas or rinsed away as excess.

Energy consumption in digital textile printing operations proves approximately 30 percent lower than conventional manufacturing approaches, reflecting the elimination of energy-intensive screen preparation, curing, and fixation processes. One-step digital printing solutions that integrate pretreatment, printing, and fixation inline eliminate additional processing steps, reducing operational costs by as much as 50 percent while decreasing energy and chemical consumption by 80 percent.

Water-based pigment inks used in modern systems eliminate hazardous chemical releases and minimize wastewater generation compared to reactive dye printing methods. This technological shift aligns with the sustainable fashion movement, wherein 94.6 percent of consumers express willingness to pay premium prices for eco-friendly options. Manufacturers adopting digital textile printing for high precision customization simultaneously improve environmental performance, reduce operational costs, and meet evolving consumer preferences for responsibly produced apparel.

Applications Across Multiple Industries

Fashion, Promotional Products, and Beyond

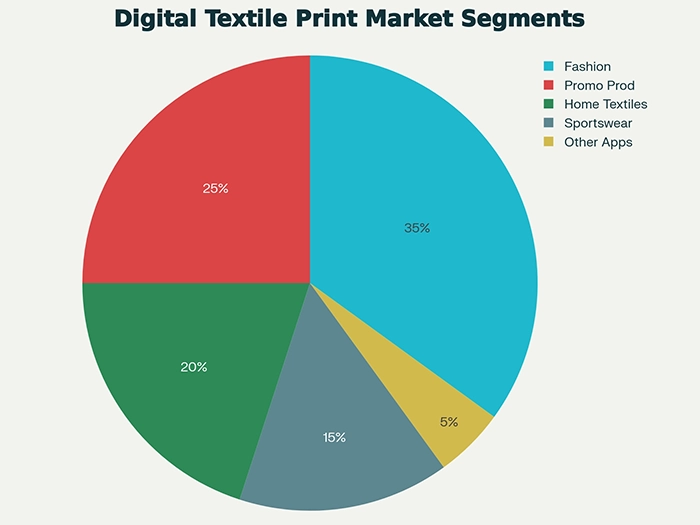

The versatility of digital textile printing technology has enabled adoption across diverse application sectors beyond traditional fashion. The fashion industry benefits from capabilities to create custom prints on various substrates—from luxury silk and premium cotton through to contemporary synthetic blends—with each fabric type capable of producing distinctly different aesthetic outcomes. Designers leverage this versatility to develop signature collections that differentiate brands through unique visual presentations.

Promotional merchandise represents a particularly dynamic application domain wherein DTG printing and DTF printing technologies deliver substantial value. Corporate branding on custom apparel, branded bags, scarves, flags, and banners achieves vibrant, durable prints that create lasting impressions on recipients. The ability to produce small quantities economically enables companies to create truly personalized promotional items, whether featuring individual names, departmental logos, or event-specific designs.

Home textile applications including custom curtains, upholstery, bedding, and decorative textiles have experienced remarkable growth as consumers demand personalization in domestic environments. Sports and activewear industries leverage digital printing’s durability and precision to create performance apparel featuring complex graphic designs, moisture-management integration, and custom fit specifications. The technology’s expanding applications continue to reveal new possibilities as manufacturers discover innovative uses for digitally printed textiles.

Technical Requirements and Best Practices

Achieving Optimal Results in Digital Printing

Successful implementation of digital textile printing for high precision customization requires adherence to specific technical protocols that ensure consistent, high-quality outcomes. Artwork resolution standards demand effective resolution exceeding 100 pixels per inch, with 150 DPI considered acceptable for standard applications and 300 DPI recommended for maximum precision work where fine details and gradients prove critical to design success. These specifications represent the resolution of the image after sizing within layout software, necessitating careful calculation when enlarging source files.

Color management protocols require calibrated measurement equipment and ICC profiling specific to each substrate type. Spectrophotometric devices enable accurate color verification and printhead calibration, ensuring that colors remain consistent across production runs and match designer specifications with high fidelity. Modern digital systems incorporate automated calibration routines that maintain color accuracy without requiring manual intervention, substantially reducing operational complexity.

Fabric preparation plays a crucial role in optimizing print quality, particularly for DTG applications on darker garments or synthetic materials. Pre-treatment of fabric surfaces enhances ink absorption and adhesion, contributing to superior wash fastness and color vibrancy. Post-printing fixation through heat or steam ensures that water-based inks properly cure within fabric fibers, creating bonds that withstand extended laundering without fading or deterioration.

Market Growth and Future Trajectory

The Expanding Landscape of Digital Textile Printing

The rapid expansion of the digital textile printing industry reflects fundamental shifts in consumer preferences, manufacturing methodologies, and competitive dynamics. DTG and DTF printing technologies have proven particularly suited to fast fashion and e-commerce environments that demand rapid product updates, diverse design offerings, and quick turnaround times. These industries’ inherent requirement for frequent design iterations and product launches aligns perfectly with digital printing’s strengths in flexibility and accelerated production timelines.

Technological innovations in automation systems, advanced printhead designs, and specialized ink chemistry continue to enhance the practical and economic viability of digital textile printing. Manufacturers including Kornit Digital, Epson, Mimaki, and others have released systems that increasingly eliminate the need for ancillary pre-processing and post-processing equipment while reducing the requirement for specialized operator expertise. This democratization of digital textile printing technology has enabled smaller enterprises and individual entrepreneurs to compete effectively in customization markets previously dominated by larger manufacturers.

Regional dynamics indicate that large-scale investments in China have particularly driven DTF adoption, with the technology’s explosive growth reflecting its suitability for the ultra-fast fashion retail sector’s specific operational requirements. As the technology matures and costs decline, adoption is spreading to additional geographic regions and industry segments, suggesting continued substantial growth throughout the 2025-2032 period.

Integration with Emerging Technologies

Smart Textiles and Future Possibilities

The convergence of digital textile printing with complementary technologies promises to unlock additional innovation possibilities. The integration of three-dimensional printing capabilities with traditional digital textile methods enables creation of intricate textile structures featuring texture, depth, and dimensional effects previously impossible to achieve. Wearable electronics incorporating conductive threads, integrated sensors, and interactive display elements represent another frontier, allowing digital printing to complement functional textile components in garments that simultaneously serve aesthetic and technological purposes.

Smart textiles incorporating embedded technology elements require precise positioning and integration of conductive and functional components with aesthetic printed designs. Digital textile printing technology’s inherent precision and flexibility make it uniquely suited to support these innovations, enabling simultaneous application of decorative prints and functional circuit elements within unified production workflows.

Conclusion

The evolution of digital textile printing for high precision customization represents a paradigm shift in textile manufacturing, enabling unprecedented combinations of design flexibility, production efficiency, and environmental responsibility. As consumer demand for personalization accelerates and fashion cycles continue to compress, manufacturers who master this technology gain substantial competitive advantages in responsiveness, creativity, and operational sustainability. The convergence of advanced inkjet technology, sophisticated ink chemistry, and intelligent automation systems has transformed digital textile printing from experimental methodology to industrial-scale production capability capable of serving diverse applications from haute couture through promotional merchandise and beyond. Looking forward, continued innovation in printing equipment, ink formulations, and complementary technologies promises to expand the possibilities further, positioning digital textile printing at the forefront of textile industry evolution for years to come.